|

|

新建网页 1

新建网页 1

新建网页 2

|

30-80cm Diameter Curved Screen

Printing Machine |

|

This machine is

mainly used for cylindrical, conical type products; Such as large and

medium-sized plastic drums, iron oil drums, stainless steel drums, garbage cans,

etc.,it can also be used for conical barrels, etc.

Drums 30 to 80 centimeters (12 to 31 inches) in

diameter can be used.

Printing pattern width (left and right) within 60 cm

(24 inches); The printed pattern is within 50 cm (20 inches) in length (front

and back).

|

|

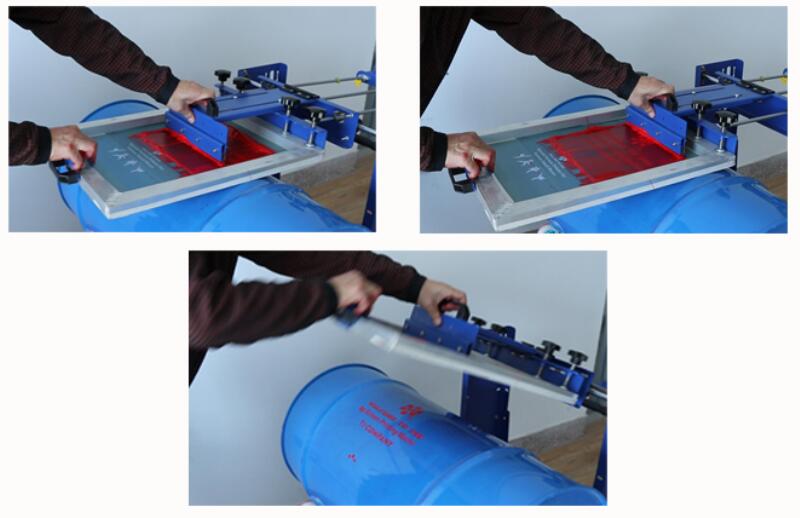

The screen plate front and back push-pull

structure, one hand press down the squeegee rack; The other hand pull the screen

frame to complete the printing. |

|

|

|

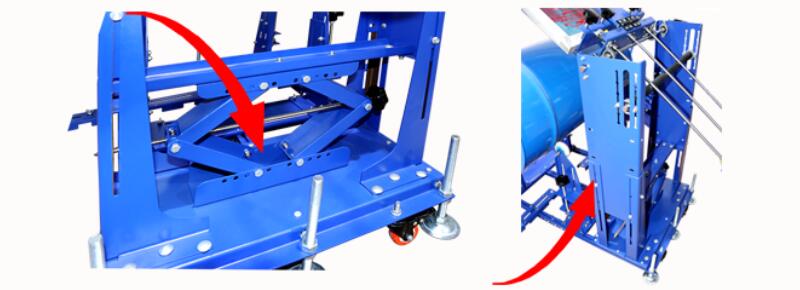

Double height adjustment structure to suit printing of different diameters. |

|

1.The rear main frame is manually fine-tuned height with a maximum adjustment

distance of 20cm. Loosen the connecting bolts of the main frame and adjust the

lifting handle by hand . After reaching the appropriate height, tighten the

connecting bolts of the main frame to complete the height adjustment.

2.The

substrate support rack manually

fine adjustment height, the maximum adjustment distance

is 15

cm; Loosen the upper and lower connecting bolts of the support

rack;

Adjust the lifting handle manually. After reaching the appropriate height,

tighten the upper and lower connecting bolts of the support frame to complete

the height adjustment.

3.For taper drum printing, it can be realized by adjusting the different heights

of the four substrate support

rack.

By adjusting the height of the support

rack,

the top of the taper drum is horizontal and fits with the bottom of the screen

plate.

|

|

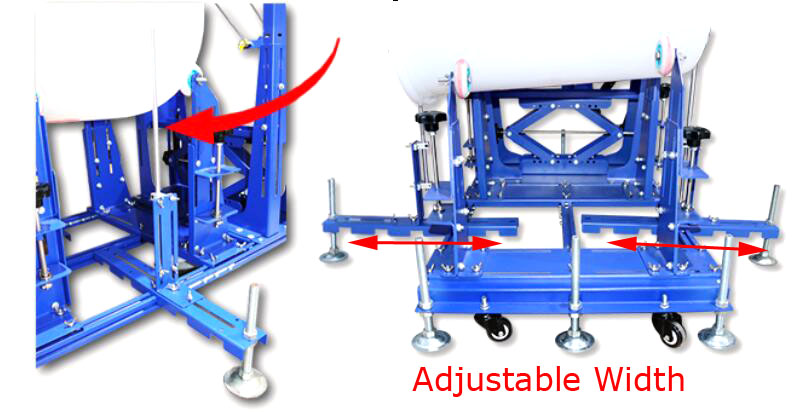

Both sides can adjust the length of the limit bar 45 cm, used to

locate the placement of the substrate, the maximum distance between the two bar

is 135 cm; The minimum distance is 25cm, the lever can be adjusted up and down,

can be used according to the need to use the limit on one side or both sides . |

|

Connect the

screen plate sliding three optical axis on both ends are installed finite

position ring, can lock the screen plate movement distance according to the

pattern printing distance.

|

|

It is equipped

with the frame fixed handle directly installed on the frame, the front and rear

push-pull is more convenient.

|

|

The lifting

height of the screen plate can be adjusted. The fixed optical shaft seat on both

sides of the sponge tube optical shaft is completed.

|

|

The scraper

fixed rack can be moved back and forth, the shortest distance from the scraper

blade to the frame chuck is 33 cm; the longest is 60cm (additional extension

plate is required)

|

|

The rubber can

be directly installed on the scraper rack, or the scraper with the wooden handle

can be fixed on the scraper rack by using self-tapping screw the tapping wire.

The width of the scraper rack is 24cm.

|

|

Substrate

support rack can be adjusted back and forth according to needs, the maximum

spacing back and forth is 45 cm; Minimum spacing is 15 cm.

|

|

The bas ies equipped with 8 pieces adjusted 20cm high support

feet; Equipped with casters; When it is necessary to move the machine, loosen

the supporting foot and when the bottom of the supporting bowl is higher than

the casters to move the machine.

|

Items included:

- 1 set of 30-80cm

Diameter Curved Screen Printing Machine(006598)

|

|