|

|

н¨ÍøÒ³ 2

|

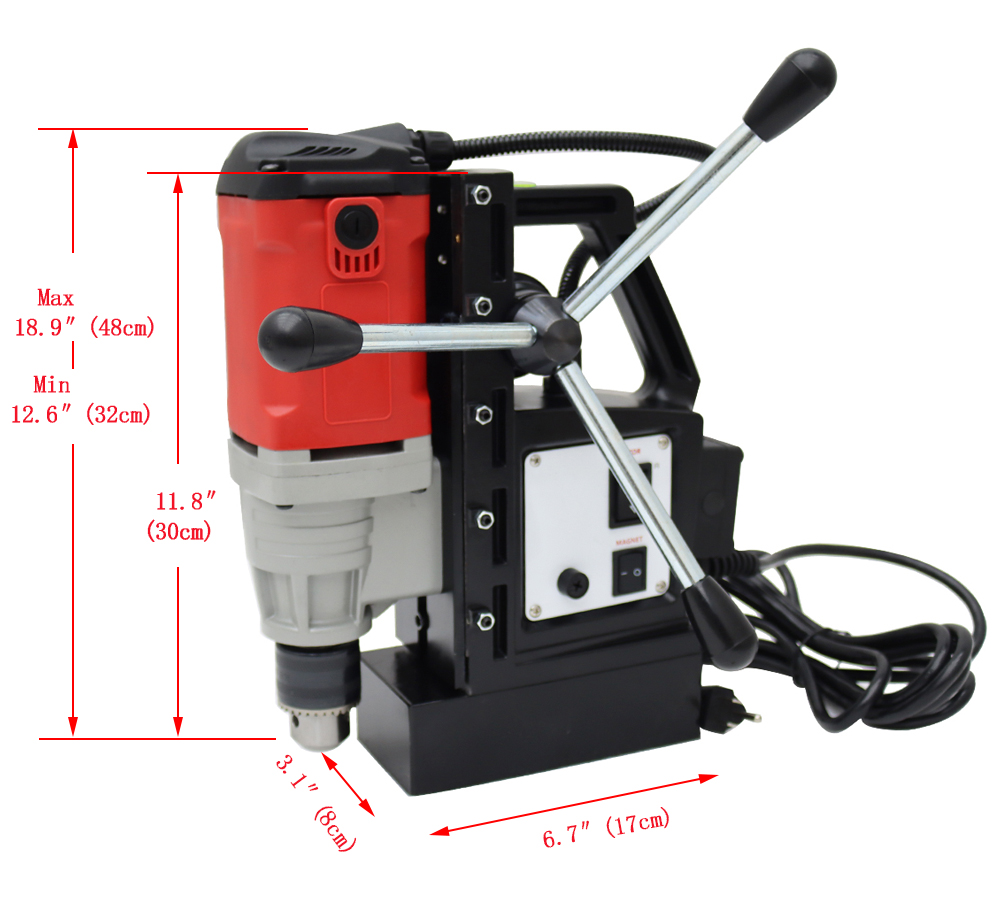

Portable Magnetic

Drill 1150W |

|

|

Our magnetic drilling rig uses

high-quality motors with a power of up to 1150W. The magnetic force is

11000N. After being

energized, the electromagnet of the magnetic drill base generates a

magnetic field that can firmly adhere to the surface of the

workpiece, achieving drilling or threading of steel plates.

Suitable for steel structures, shipbuilding, equipment manufacturing,

equipment installation, bridge engineering, wind power

generation, oil drilling platforms, power construction, railway

manufacturing and other fields. |

|

Parameter |

|

Voltage |

110V |

|

Power Input |

1150W |

|

Max.attraction |

11000N |

|

Rate frequency |

60Hz |

|

No-load speed |

0-880rpm |

|

Core drill dia |

/ |

|

Twist drill dia |

13mm |

|

Max tapping dia |

M8 |

|

N/G weight |

23.4lb(10.6kg)/25.4lb£¨11.5kg£© |

|

Package Size |

13.9*6.3*13.6in(35*16*34.5cm) |

¡¡ |

|

|

|

Detail |

|

|

|

Control Panel

Two switches, respectively control machine operation and

magnetic base, easy to operate. |

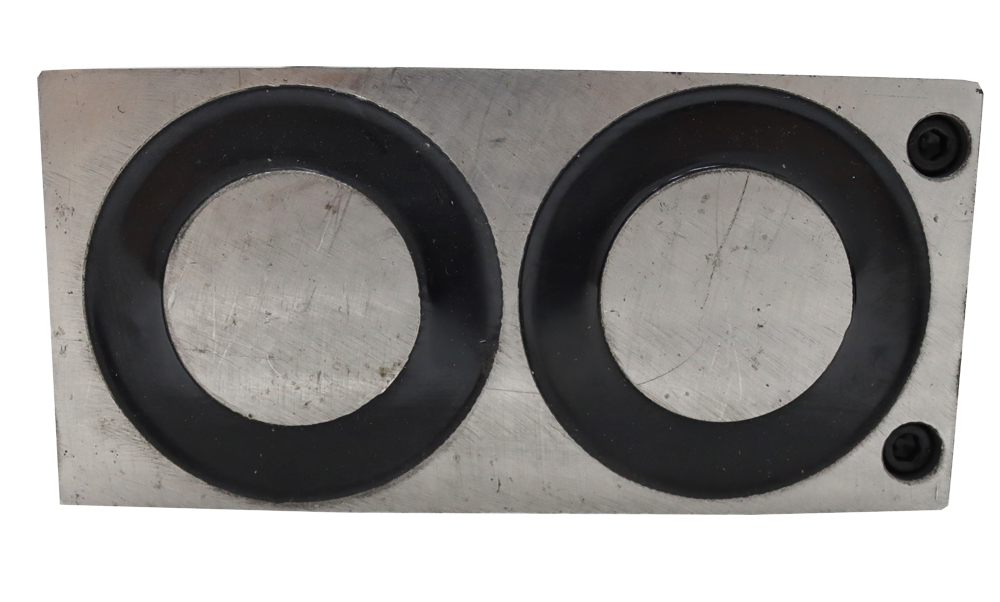

Magnetic Base

Super suction magnetic seat, suction more than

11000N, safe and reliable, side suction can be suction. |

|

|

|

Guide Rail Design

Double dovetail guide rail design, high strength wear-

resistant treatment, more durable. |

Speed Adjustable

Stepless speed regulation, between 100-670rpm,

arbitrary adjustment. |

|

|

|

Lifting Handle

Rocker type lifting handle, can accurately control the height

of the head lifting. |

Level

By observing the level, determine whether the machine

is in a horizontal position. |

|

|

Operation Precautions |

1. Insert the power plug, align the drill

bit with the machining position, and then turn on the electromagnetic

switch. Use a magnet to adsorb onto

the surface of magnetic materials such as steel, ensuring that there are

no debris on the surface, and check if the magnetic force is normal. The

required thickness of the steel plate should be at least 6 millimeters

or more on the flat surface.

2. Place the magnetic drill near the required drilling area, select

suitable adsorption materials, and thread one end of the safety belt

into the lifting

hole of the rack. Tie the other end to a sturdy support and thread it in

with a 100mm outlet. Then tighten the bolts of the fasteners and try to

pull

them with force without loosening or shifting.

3.Open the drill switch, check whether the drill is beating, the sound

is smooth, if everything is normal, you can turn the handle to feed.

4. The beginning of the feed should be slow, not hard, the feed amount

is generally about 0.05mm, do not exert too much force to prevent

overload.

5. If the drill suddenly stops for some reason, the power switch must be

turned off immediately (please turn off the magnetic base control

switch).

6. Continuous use of 2-3 hours after the need to rest for a period of

time to prevent the magnetic seat due to overheating and burn out. |

| Item Number: Portable

Magnetic Drill 1150W 027338 |

| ¡¡ |

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us

with low cost. |

|