|

|

63In Full-Auto

Pneumatic Low Temperature Laminating Machine(Excluding air compressor) |

|

|

|

|

|

|

.jpg) |

|

Product

Overview |

The novel laminating machine can

cover drawings with different films through the cold press technology

and the heating function. The finished drawings will be waterproof,

colorfast and colorful. The films with or without bottom paper can be

used by our excellent machine. The pneumatic laminator also has a

function for easily cutting the drawings covered with films. It will be

a satisfying partner for your work and business.

Our Customer Service System will offer you a long-term and reliable

technical service!

Please believe that we are always pursuing outstanding technical

performance and excellent quality!

Note: The machine should be used with the 8L

air compressor prepared by the customer. |

|

Product

Parameters |

|

Max. laminating width |

63In (1600mm) |

|

Max. laminating thickness |

1.38In (35mm) |

|

Max. Laminating speed |

10m/min |

|

Temperature adjusting range |

Room temperature-140℉ |

|

Roller lifting way |

Using cylinders and bilateral linkage promotion |

|

Roller heating type |

Within the infrared heating |

|

Preheating time |

10-15min |

|

Diameter of upper and lower rubber rollers |

5.12in (130mm) |

|

Motor power |

120W |

|

Heating rod power |

1500W |

|

Rated input voltage |

110V |

|

Net weight |

293Lb |

|

Non-contact infrared temperature measurement

system |

Electric foot switch |

|

.jpg) |

|

Product

Features |

|

| The film

supporting rods can effectively support films with/without liner

paper, can be conveniently assembled and disassembled, can be

selected for supporting different films as needed, is durable

and firm and has a long service life. |

|

The film stripping

rod is a large-diameter aluminum alloy rod, is subjected to

surface oxidization treatment, can effectively reduce vibration

and noise in the working process and avoids chatter marks in the

film stripping process. |

|

|

|

|

|

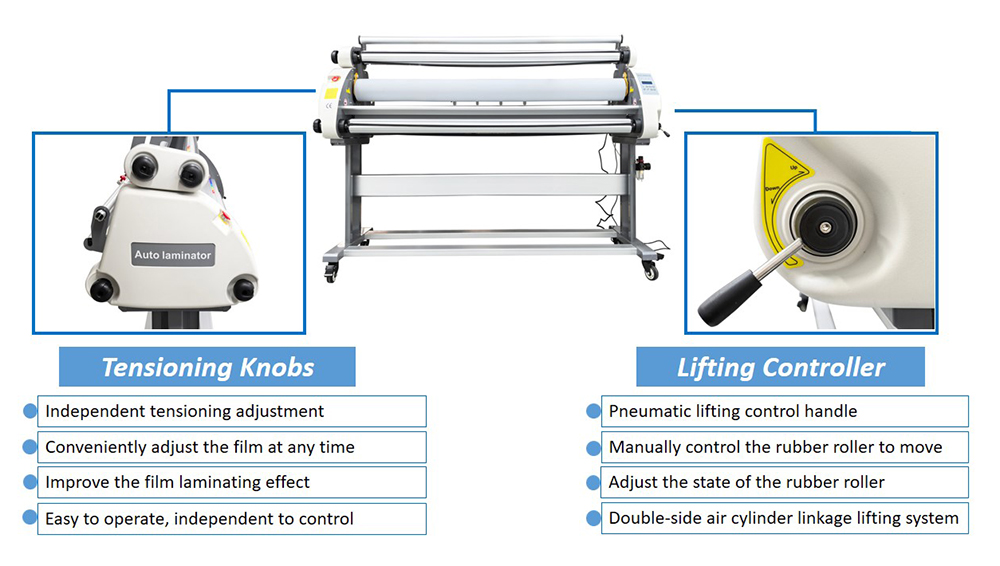

Independent tensioning knobs are used for adjusting the

tensioning degree of all supporting rods, can control the film

at any time and improve the film laminating effect, and are easy

to operate and control and high in working efficiency. |

|

The pneumatic lifting

control handle can be used to manually control the rubber roller

to move up and down, the double-side air cylinder linkage

lifting system can effectively improve the lifting effect, and

the using effect is good. |

|

|

|

|

| The

emergency switch can be used to immediately stop the machine in

emergency, can be easily pressed and rotated, effectively

protect the personal safety and provides safety guarantee for

operators. |

|

The unique

microcomputer control panel is adopted to control the machine,

the user can select the proper laminating function freely and

set different parameters, and the machine state can be clearly

displayed. |

|

|

|

|

|

The high-quality heat temperature resistant

rubber roller is used for lamination, the maximum laminating

width can be 63in, the maximum laminating speed can be 10m/min,

and the rubber roller can ascend and descend pneumatically.

|

|

The pressure gauge

can display the pressure in real time, the operator can observe

and monitor the pressure change conveniently, reference data are

provided for recording the machine state, and overpressure and

other accidents can be effectively avoided. |

|

|

|

|

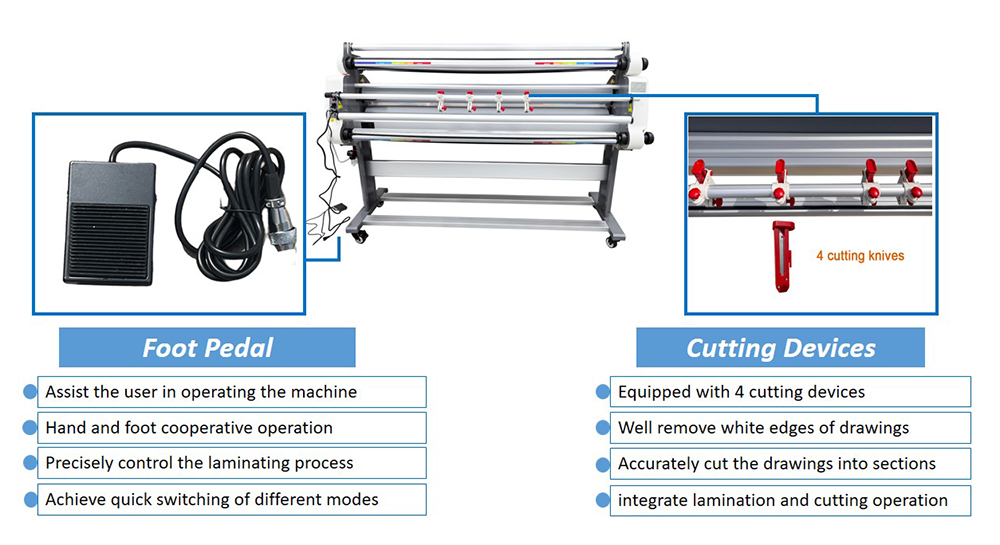

| The foot

pedal can assist the operator in operating the machine, the

operator can precisely control the laminating process through

hand and foot cooperative operation, and the manual mode and the

automatic mode can be quickly switched. |

|

The four cutting

devices are freely installed on the supporting rod, can

effectively remove the white edges of drawings and precisely cut

the drawings into sections as needed, and lamination and cutting

operation can be conducted simultaneously. |

|

|

|

|

| The

collecting rods can easily collect finished products and back

paper, save time and labor, reduce the labor intensity and are

firm and durable in structure and convenient to remove and

install. |

|

The universal wheels

are arranged at the bottom of the machine so that the machine

can convenient to move and fix and adapt to different working

environment. |

|

|

Instruction of

Control Panel |

|

|

|

|

Application |

|

The Pneumatic Low Temperature

Laminating Machine can be widely applied to lamination of wedding

photos, posters, advertising photographs, book covers, documents,

calligraphy and painting, invitations and so on, and is suitable for the

enterprises and industries of advertising, printing, photography,

packaging and the like. |

|

|

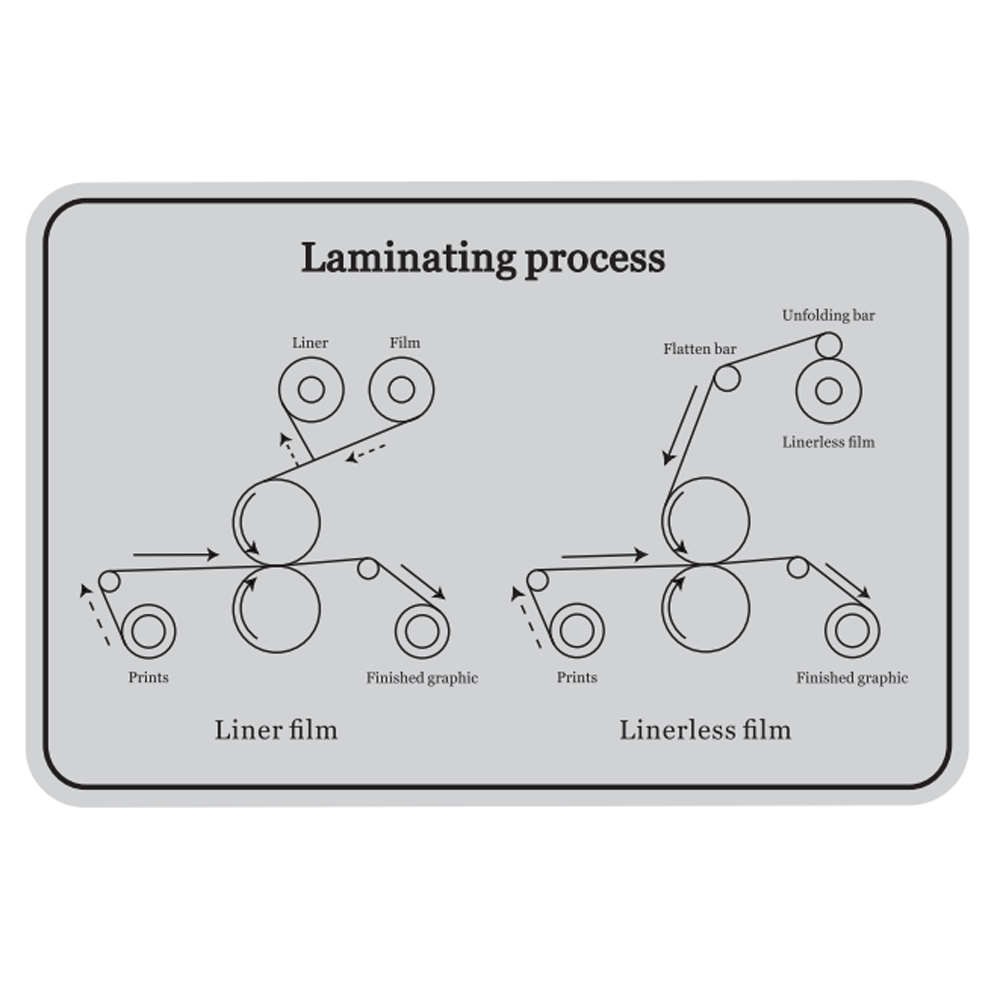

Laminating

Process |

|

|

Operation method |

1. Connect the air compressor. (No air

compressor is included, and customers need to use their own air

compressor.)

2. Connect the 110V power supply and turn the emergency switch. Both

cold lamination and thermal lamination can be conducted, and the

detailed operation method can refer to the following video.

https://youtu.be/F_RfF5SYt_o |

|

Pay attention to safety when using, do not put hands into the machine

during operation.

|

|

Item Number (120076):

1 x 63In Full-Auto Pneumatic Low Temperature Laminating

Machine(Excluding air compressor) |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |