|

|

|

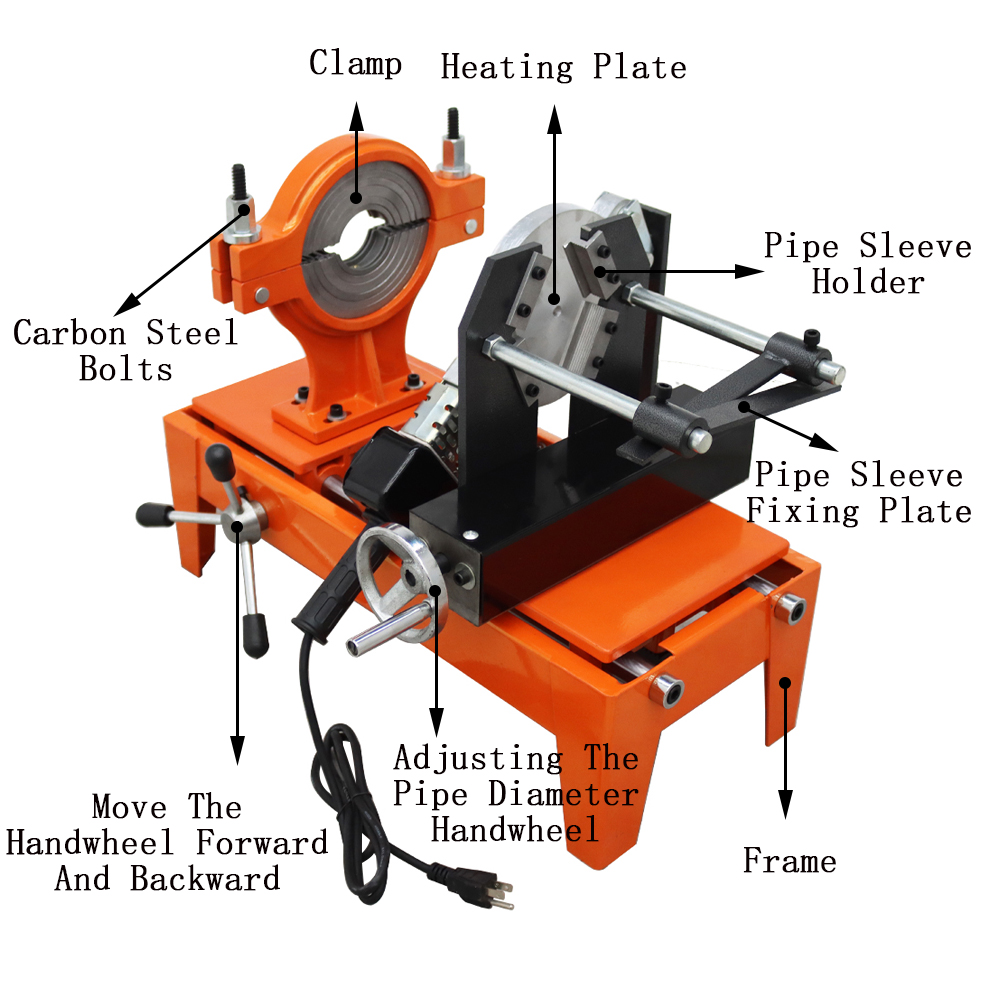

Pipe Welding Machine Pipe Soldering

Iron Plastic Hot Melt Tool |

|

|

|

|

|

|

|

Description:

This product is suitable for hot melt socket

welding of thermoplastic pipe such as PPR/PE/PB.High quality design and

construction provides an

excellent machine for welding both on the worksite and in the factory.

The use of high quality Aluminum casting allows for lower weight without

compromising strength and performance. |

|

Advantage:

1. Accurate temperature control, high safety index,

and strong environmental adaptability.

2. The heat transfer plate is made of aluminum alloy, with high thermal

conductivity and strong antioxidant energy.

3. The structure is sturdy, convenient and fast, and not easy to leak.

4. The hot melt mold head adopts non stick

high-temperature coating technology, with a long service life.

5. Replacing the mold head can be used for

connecting plastic pipes and fittings of various caliber sizes

(specifications: φ 63-160mm). |

|

|

|

|

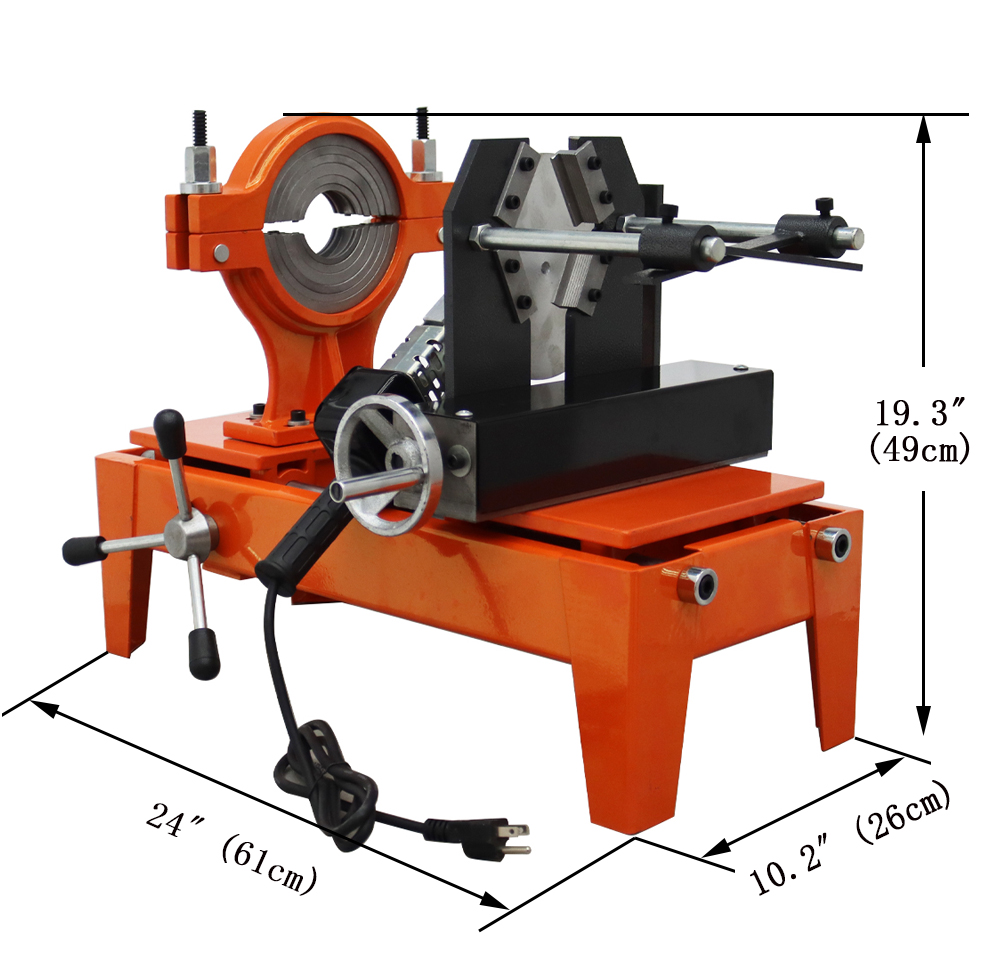

Specifications:

| Model No. |

2.48-6.29”(63-160MM)

|

| Materials |

Aluminum alloy casting, 45#

steel |

|

Welding level(Φ) |

63mm(2.48”)、75mm(2.48”)、90

mm (3.54”)、

110 mm (4.33”)、160 mm (6.29”) |

| Docking

deviation |

≤0.3mm |

| Power of Heater |

110V |

| Working

temperature |

300℃ |

| Temperature

deviation |

±5℃ |

| Environment

temperature |

-5℃-40℃ |

Time required

to reach

soldering temperature |

<20min |

| Materials can

be welded |

PE PPR PB PVDF

|

| Weight |

117.7LB(53.5kg) |

| Package Size |

29.5*19.7*22.1"(75*50*56cm) |

|

|

|

Details: |

|

|

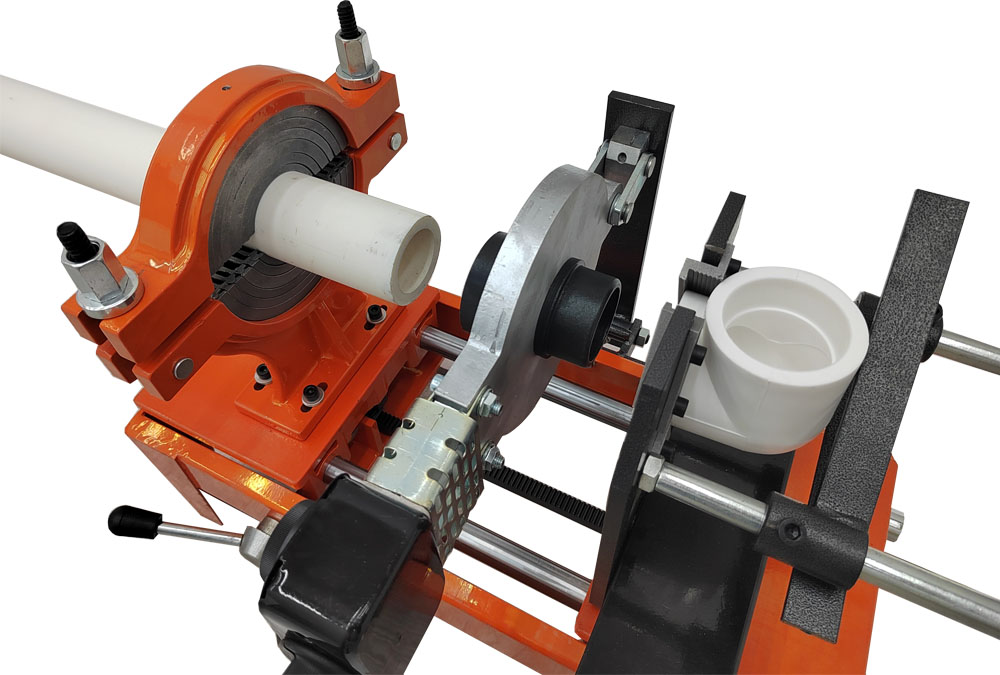

Left and right division

of labor fixture

The left side can fix the pipe, the right side

can fix the pipe, and the

middle can remove the heating plate, replacing manual welding.

The

welding effect is good, labor-saving and worry free. |

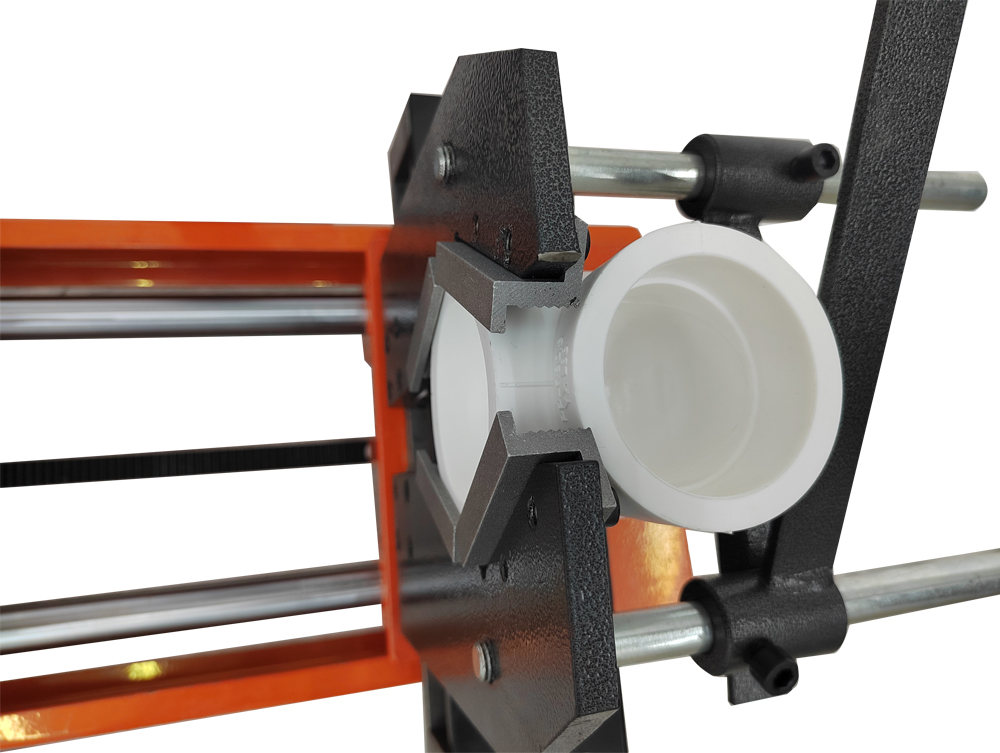

Card slot type retainer

Firmly fix the pipe fittings to prevent them from

falling off. |

|

|

Thickened high power

heating plate

Aluminum heating plate for faster heat conduction

and lighter weight. |

Adjustable top column

With the front slot fixator, the pipe fittings

are firmly supported, the position

can be adjusted at will, and then locked. |

|

|

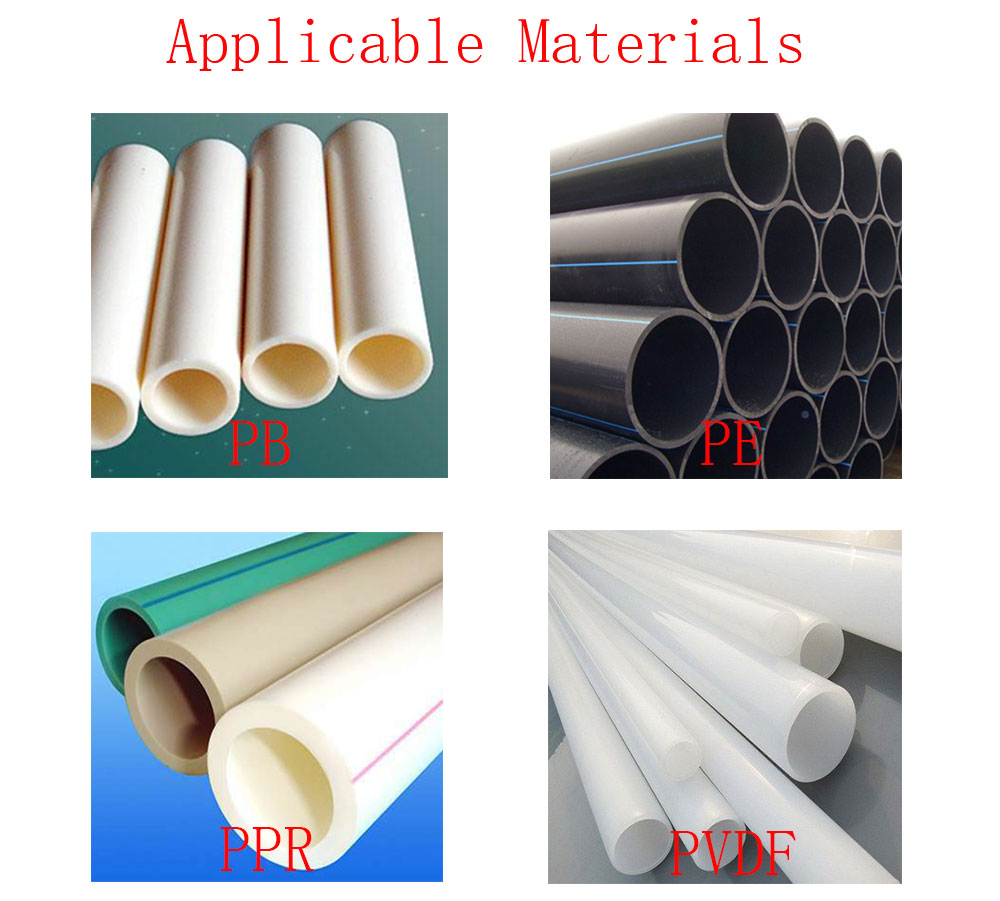

Applicable

Materials: |

|

|

Note: |

1. Fix the welding device and install the heating end.

Place the welding device on the rack, install the corresponding heating

die according to the

required pipe specifications, and tighten it with an internal hexagonal

wrench. Generally, the small one is at the front end and the large one

is at the

rear end.

2. Turn on the power and pay attention to the changes in the indicator

light until the welding machine enters the working temperature control

state

before starting operation.

3. Push vertically cut pipes and fittings into the fusion splicer die

without rotation, and operate as required. After reaching the heating

time,

immediately remove the pipe and fittings from the mold head and quickly

and evenly insert them into the required depth without rotation, forming

a

uniform flange at the joint.

On the Eccentricity Problem

1. If the top and bottom are not aligned, the pipe needs

to be raised to the same level as the fixture.

2. If the left and right are eccentric, the screws on the pipe clamp can

be loosened and the position can be adjusted according to actual needs. |

|

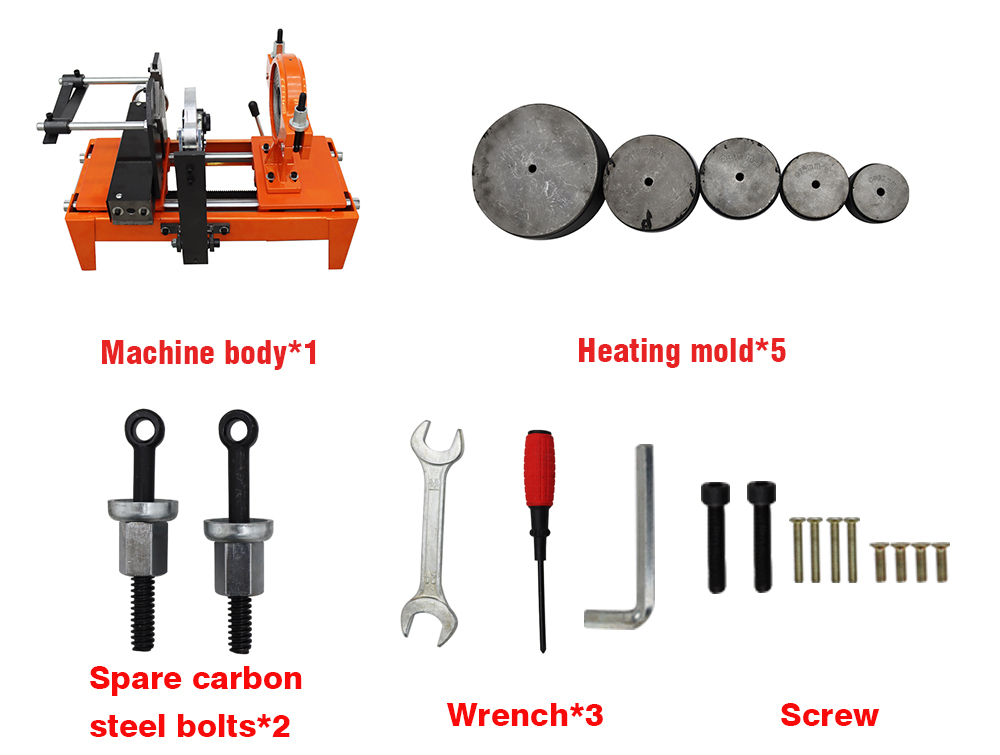

Packing List: |

|

|

Item Number: Pipe Welding Machine Pipe

Soldering Iron Plastic Hot Melt Tool 145035 |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|