|

|

|

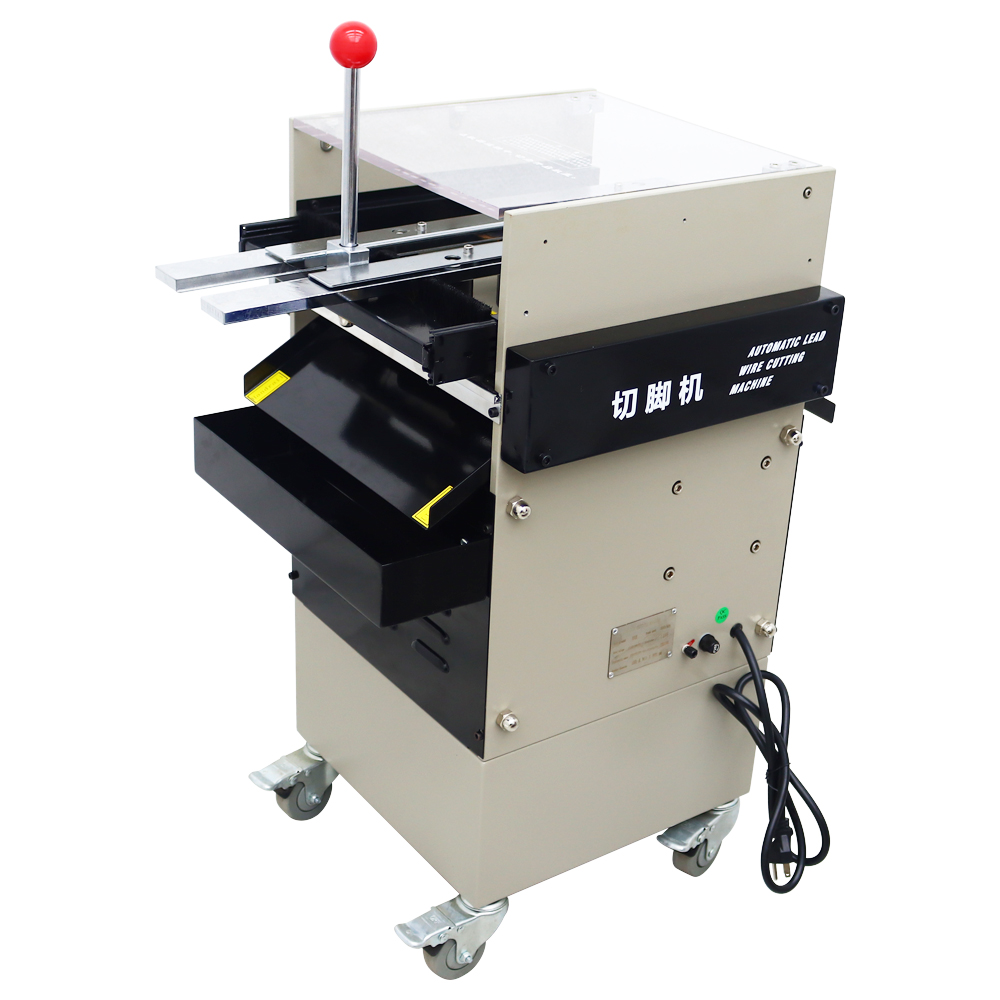

110V Semi automatic PCB foot cutting machine |

|

|

The breadboard wipe cutting machine is mainly applied in

cutting the unwanted pin after the welding of parts of

apparatus and this machine is assembled by parts made

with exquisite craftwork. The key parts are dealt with

grinding , and the imported bearing assembled wipe

cutting machine grinding consistency is excellent, the

rotating speed of blade is fast and is very

efficient and convenient to operate with

little noise. The double lead rail is adjusted

synchronously , the height of wipe cutting is adjustable

and the outlook is attractive. "Continuous improvement,

lasting and efficient, clients first" is our quality

tenet, it is our honor to serve you.

|

|

Instruction

of adjusting |

1.Open

the package and read the instruction carefully and check

the accessories (refer to term 7 in the instruction)

2.Check the body of machine for any abnormal phenomena,

if so , contact the local agent as soon as possible

3.After conforming the good connection of the case

earth, plug in.

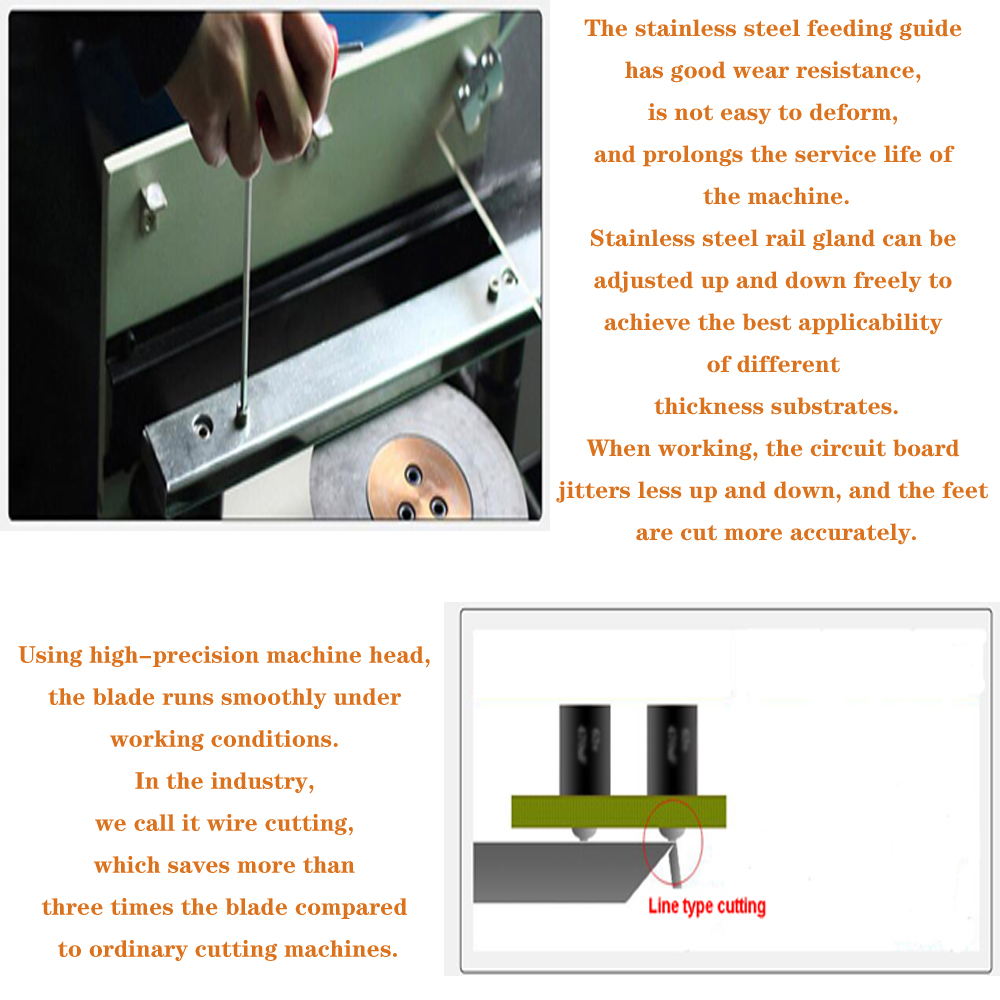

4.First adjust the double lead rail travel route

biggest, unscrew the gland bush screw(gland bush screw

is right-handed screw )with 8# inner hexagonal wrench

counterclockwise,take out the blade gland bush and clean

up both sides of tool apron, blade, gland bush with

clean and soft cloth. Then place gently the blade on the

base(surface up). Next ,place the blade gland bush on

the blade, screw down the gland bush screw with 8# inner

hexagonal wrench clockwise. When unloading the blade,

use the enclosed dismantled stick to fix the tool apron.

5. Rotate the adjusting hand wheel, adjust the width

between the lead rails, and place one wanted placode of

wipe cutting machine on the entrance and exit port

respectively. Rotate the hand wheel until the placode at

both ports slide properly in the lead rail.

6.Four sets(three screws per set)assembling screws that

are equipped on top of lead rail bland bush are used to

adjust the thickness of placode. During the adjusting

first unscrew three perch screws among them and put

placode inside and then adjust two lower order screws

besides until they fit and screw down the middle screw.

Operation are the same for four sets and adjust placode

to slide properly inside the lead rail

7.Adjusting of height of wipe cutting machine : screw

down lead rail retaining screw and adjust the big screw

cap until the distance between blade and lead rail meets

the requirement then screw down lead rail retaining

screw. When adjusting lower avoid any friction between

lead rail and blade for fear of damage to blade.

8. The height of wipe cutting of wipe cutting machine

was adjusted as 1.5mm when it leaves factory and the

thickness of textile board was adjusted as 1.2mm. When

adjusting is necessary please adjust according to method

mentioned above.

|

|

Features |

|

|

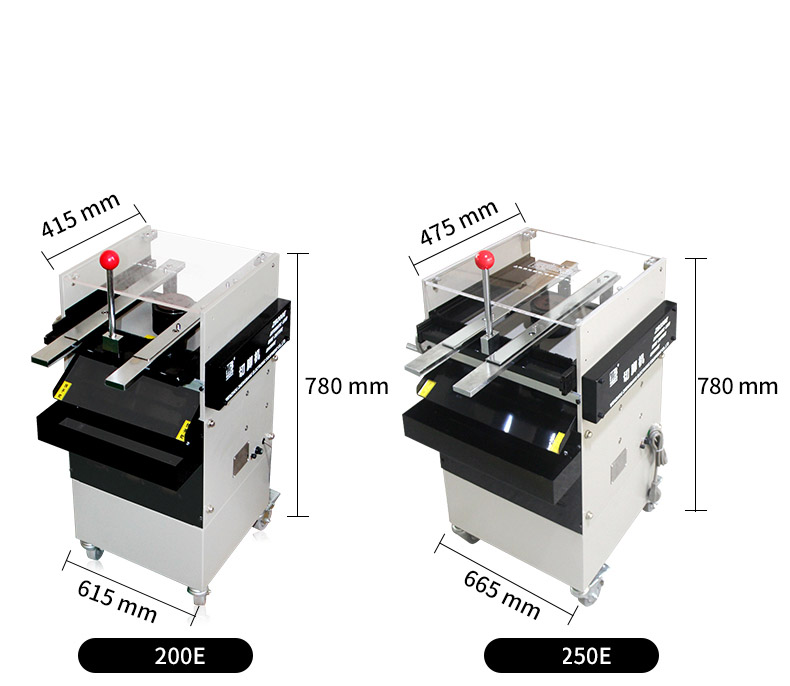

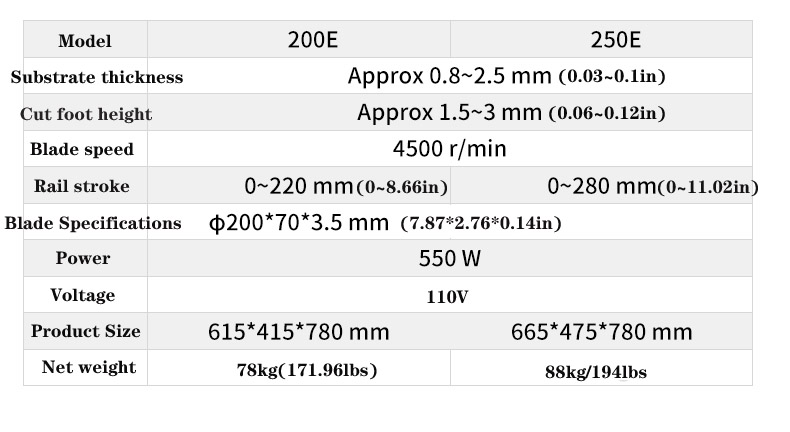

Specifiction |

|

|

|

Notice: We

send a blade($350) as a gift. |

|

Operations |

|

1.

Place the welded breadboard on the adjusted wipe cutting machine and

insert the lead rail down the leading-in of lead rail.

2.Push dexter feed hand shank and push placode advance at constant

speed

3.Repeat step 1,2 and finish cutting the welded placode.

Notice: When the placode moves avoid moving too fast, and moving too

fast can directly shorten the use life of blade and even endanger

safety. |

|

Maintenance |

Wipe cutting machine

is the mechanic equipment of high accuracy and with high speed and

the constant maintenance prolongs its use life

1.The rotating part needs constant lubrication.

2.Clean up the cut pin

3.If the transmitting triangle strap is damaged, it needs immediate

replacement and the specification is (0-450)

4.The blade should not leave cutter head for too long, lubricate the

cutter head when necessary if it leaves for several days. |

|

Notice |

|

1.When the machine

is in operation avoid putting hands into the machine.

2. This machine must work in the state of good earth connection

3.Cut off the power when installing or dismantling blade or in case

of emergency

4.Cut off the power in sace of a blackout.

5.This machine should not be used in humid, flammable, corrosive,

dense bug dust-filled environment.

6. Non professional repairmen are not allowed to dismantle the cover

to repair it personally .

7.Do not open the cover when the machine rotates.

8.Operate the machine according to instruction strictly; otherwise

out factory takes no responsibility. |

|

Item Include(151027) |

1.A set of 110V?Semi automatic PCB foot cutting machine

2.A set of Blade

|

|