|

|

|

Single head automatic

servo paste liquid

dual purpose filling

machine |

|

|

|

|

|

|

|

|

This fully

automatic paste filling machine has functions such as automatic

conveying, automatic filling, no bottle no filling, stuck bottle

positioning and lifting filling.

This machine has a

beautiful and elegant appearance, is intelligent, and has a high

qualification rate. It is suitable for filling different bottle types in

industries such as food, pharmaceuticals, daily chemicals, pesticides,

cosmetics, etc.

It can be used for

both stand-alone production and online production.

This machine has a

reasonable design, compact structure, beautiful appearance, stable and

reliable performance, high filling accuracy, strong adaptability, simple

operation, and convenient maintenance.

This machine has the

characteristics of stable and reliable performance, high filling

accuracy, strong adaptability, simple operation, and convenient

maintenance.

This machine can be

used to fill semi fluid, paste, viscous body, sauce and various

materials containing small particles, such as honey, syrup, jam, peanut

butter, sesame paste, tomato paste, Doubanjiang, shrimp paste, Apple

sauce, Salad dressing, Caviar and other various paste and liquid

materials. |

|

|

|

Note that the air

pressure should reach 0.6MPa to work normally. Please ensure the air

pressure of the air pump when working.

(Note:We only sell

machines, do not match air compressors,

customers need to buy

their own.)

|

|

Product parameter: |

|

|

Voltage: |

110V/60Hz |

|

Material: |

The

surface is stainless steel |

|

Power: |

900W |

|

Filling accuracy: |

≤±0.5% |

| Production speed: |

10~25bot/min |

|

Filling volume: |

100-1000 |

|

Conveyor size: |

120*10cm |

|

Air consumption |

≥0.1m³/min |

|

Equipped with air pressure: |

0.4-0.6 MPa |

|

Bottle height: |

10~28cm |

| Bottle diameter: |

within 10cm |

|

Applicable pressure (Mpa): |

≥0.4 |

|

|

Feature: |

|

|

The barometer and the air inlet, the

air inlet is connected with the air compressor, easy to operate, stable. |

|

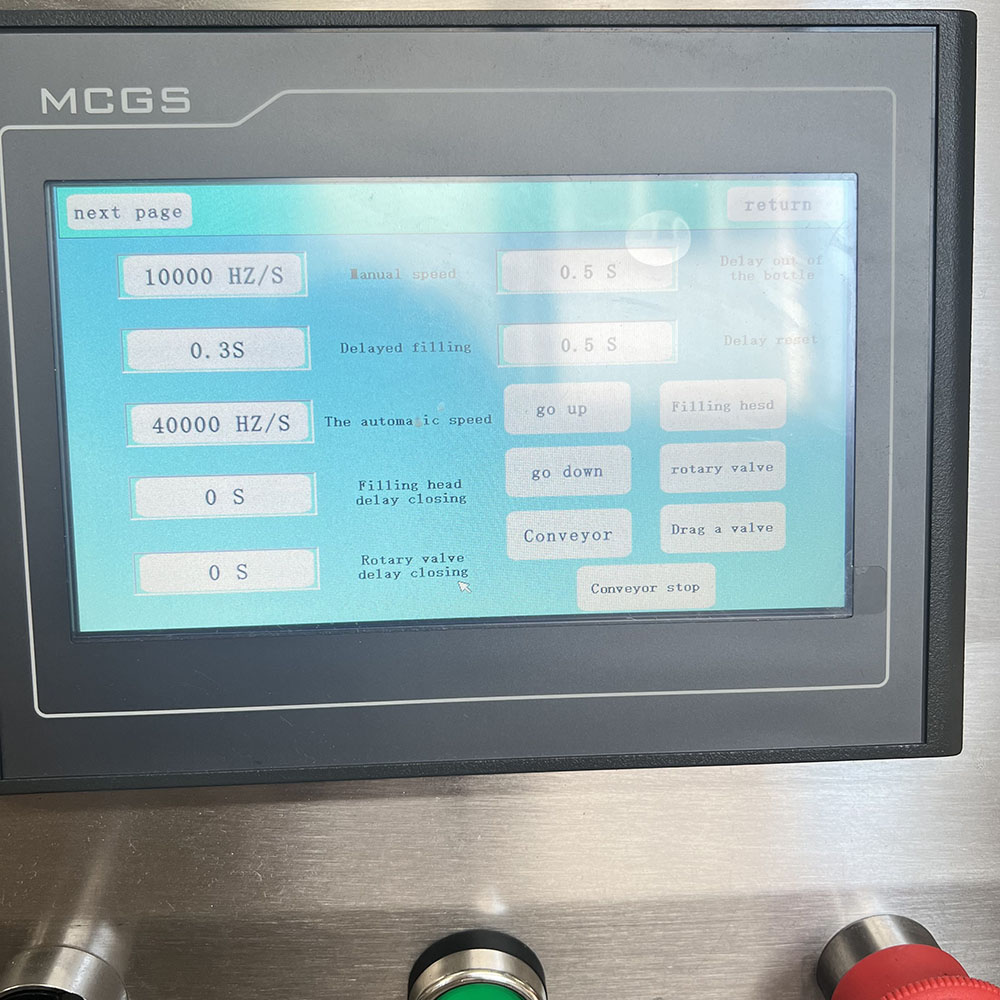

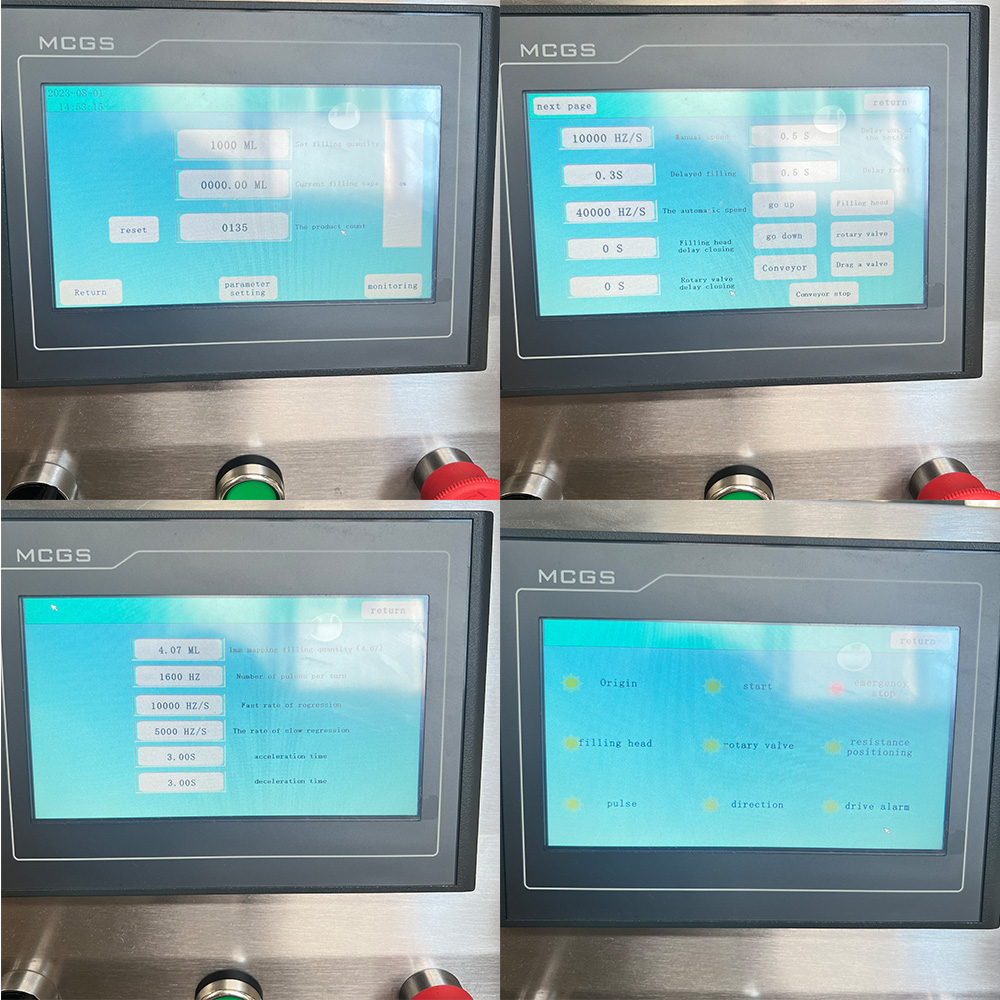

The machine is equipped with high

quality touch screen control panel, it is more convenient to adjust and

test working parameter in real time,this is good for control the machine

and can prevent from machine error. |

|

|

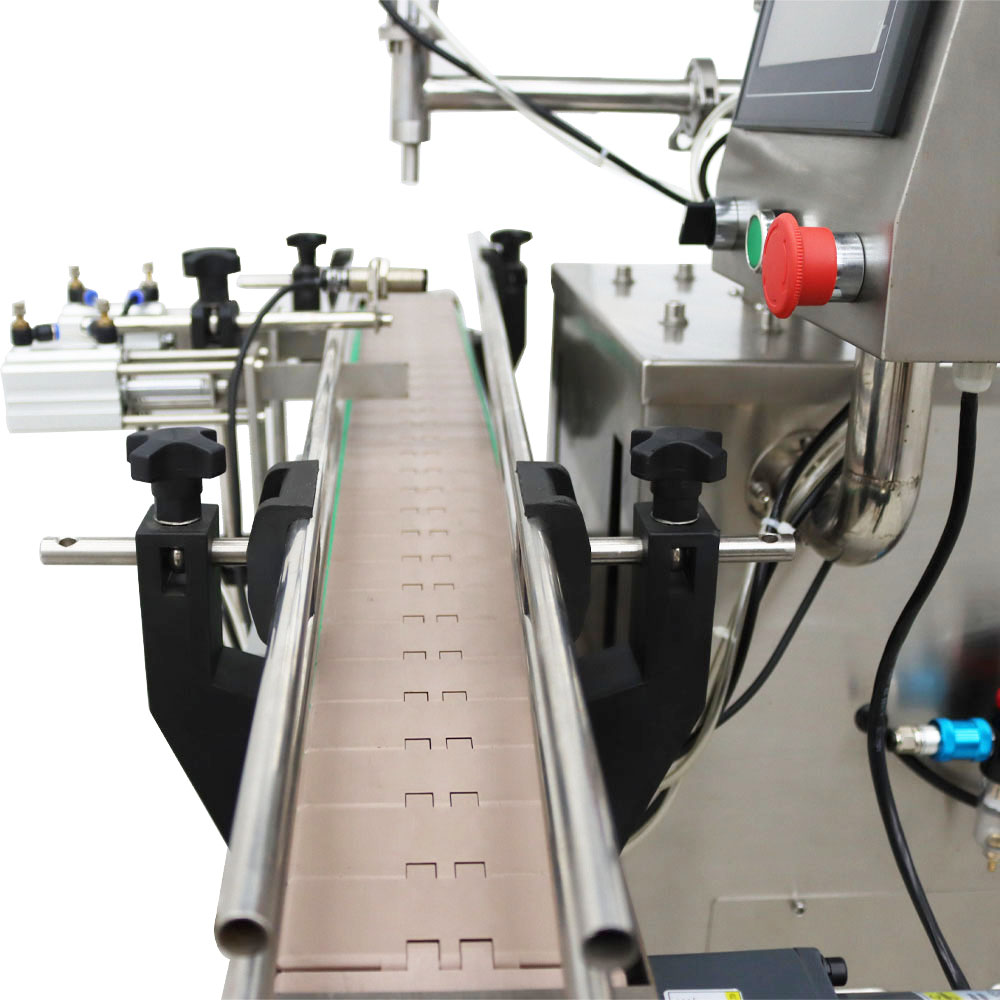

Emergency stop switch

Emergency stop button can stop machine action immediately.

|

|

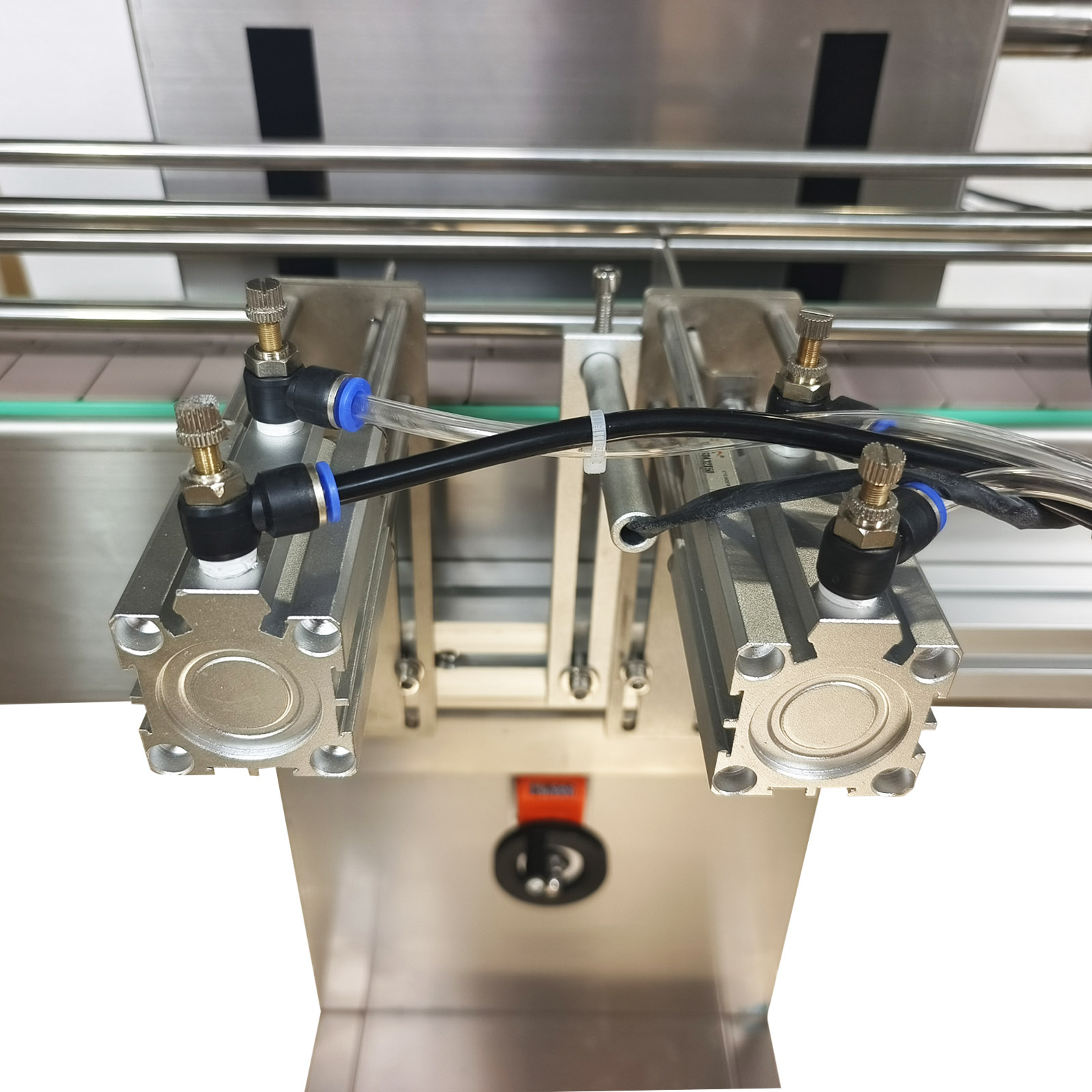

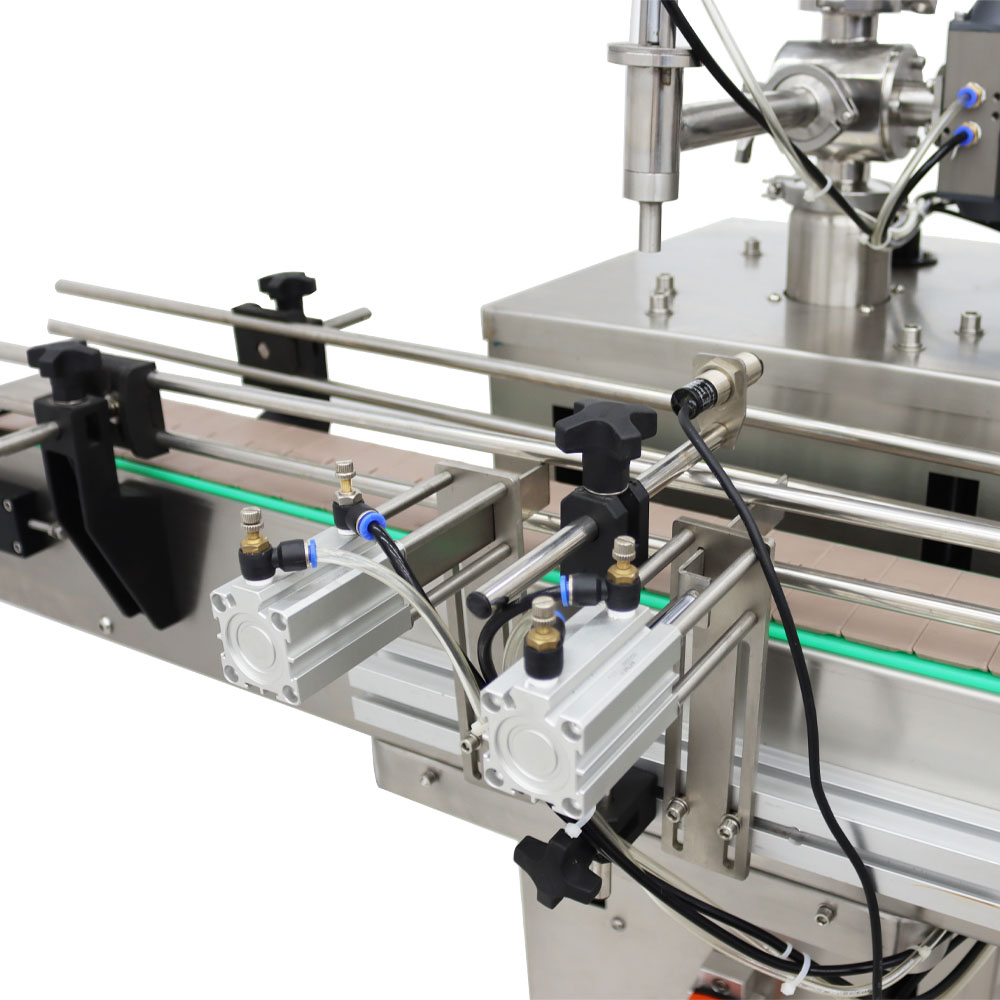

This machine is equipped with a

pneumatic filling assembly and a three-way valve, suitable for filling

liquid/paste with fine particles. (Customers can pay us to customize

multiple filling nozzles, effectively improving work efficiency and

adapting to different filling needs) |

|

|

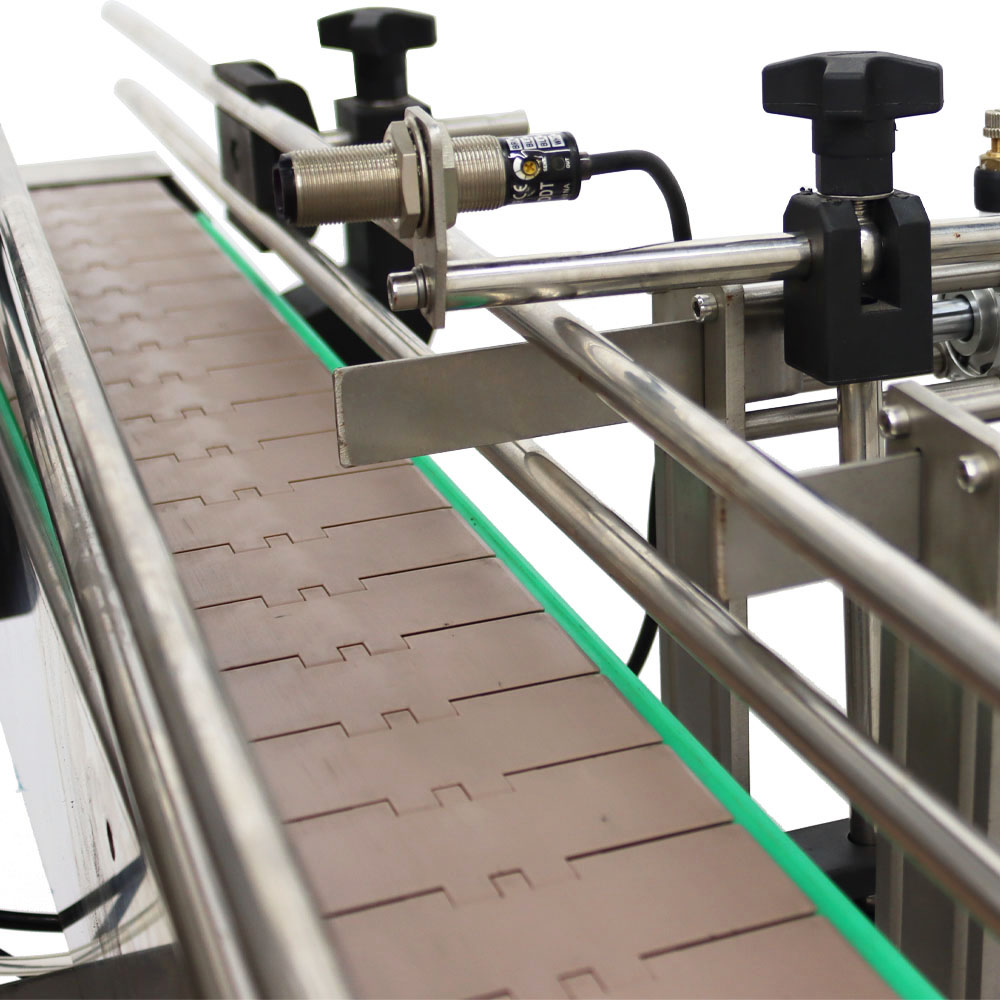

The electric eye is designed to

detecting passing by bottles and control the machine to fill liquid into

bottles.With this,the machine can work automtically and can work with

automatic capping/ labeling machine to realize automated production. |

|

This machine is equipped with a

high-quality conveyor belt, which can transport bottles to the filling

port to fill materials, making it more convenient. |

|

|

Detachable clasp, one button cleaning,

no screws. Easy to clean, save time and effort. |

|

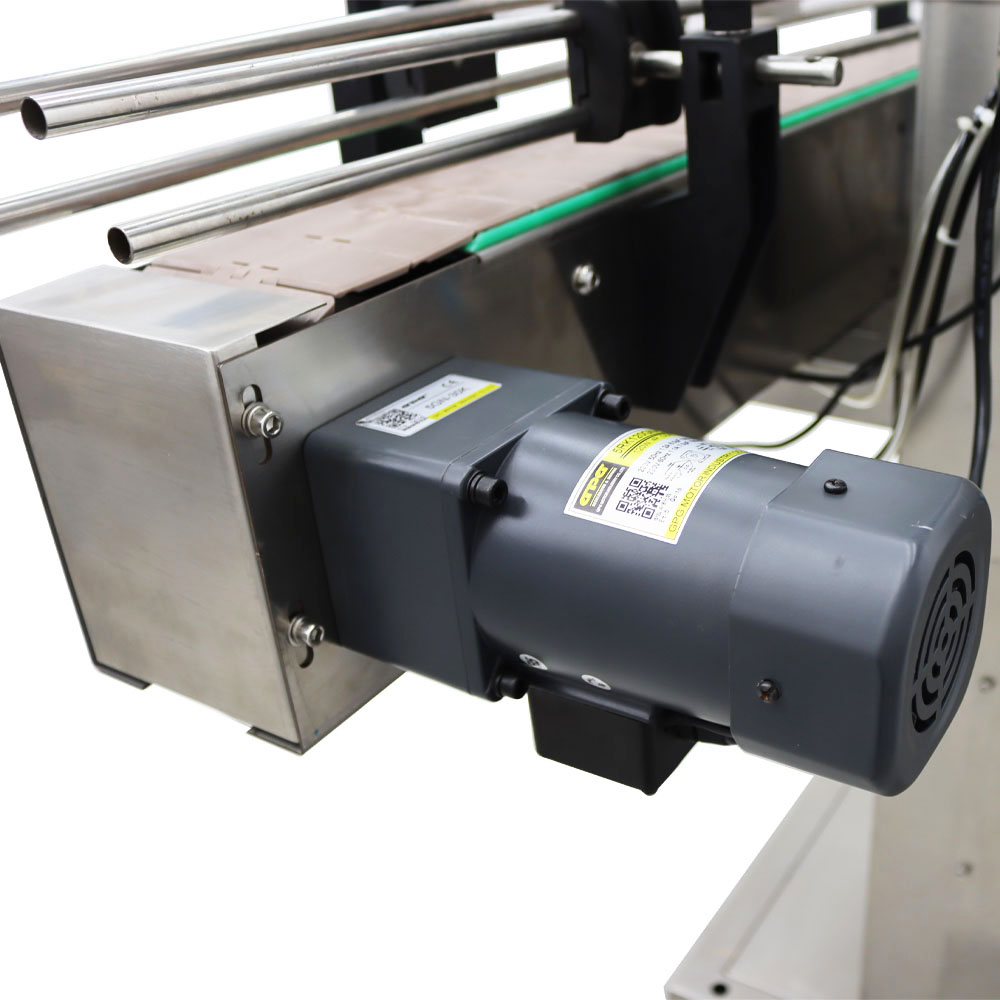

This machine adopts high-quality motor

with stable performance. |

|

|

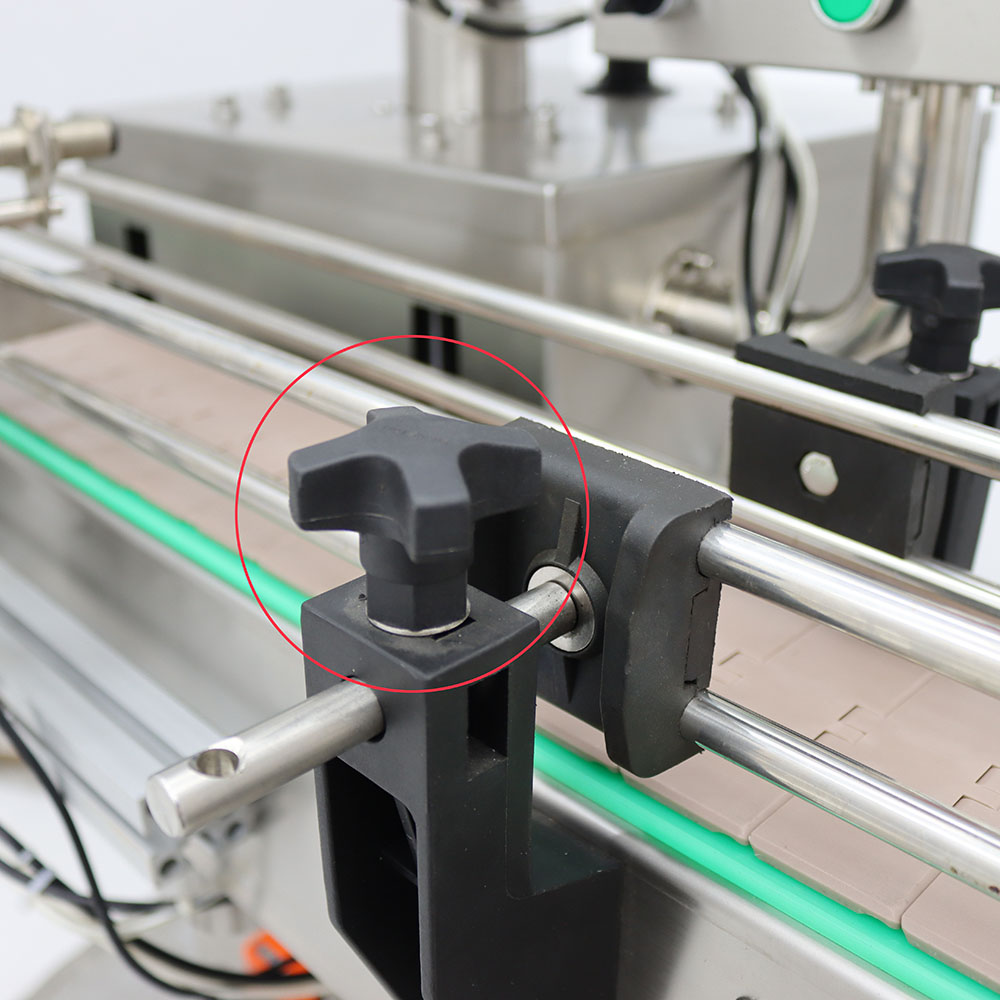

This

machine is equipped with an adjustable guardrail knob, which can adjust

the width of the guardrail according to the diameter and

height of the bottle, making it more convenient. |

|

This machine is

equipped with high-quality chain plate conveyor belt, which is more

durable; And equipped with a conveyor belt controller, the speed of the

conveyor belt can be adjusted according to customer needs. |

|

|

This machine is equipped with a lifting

handwheel, and customers can adjust the overall height of the conveying

device to accommodate bottles of different heights by adjusting the

handwheel. |

|

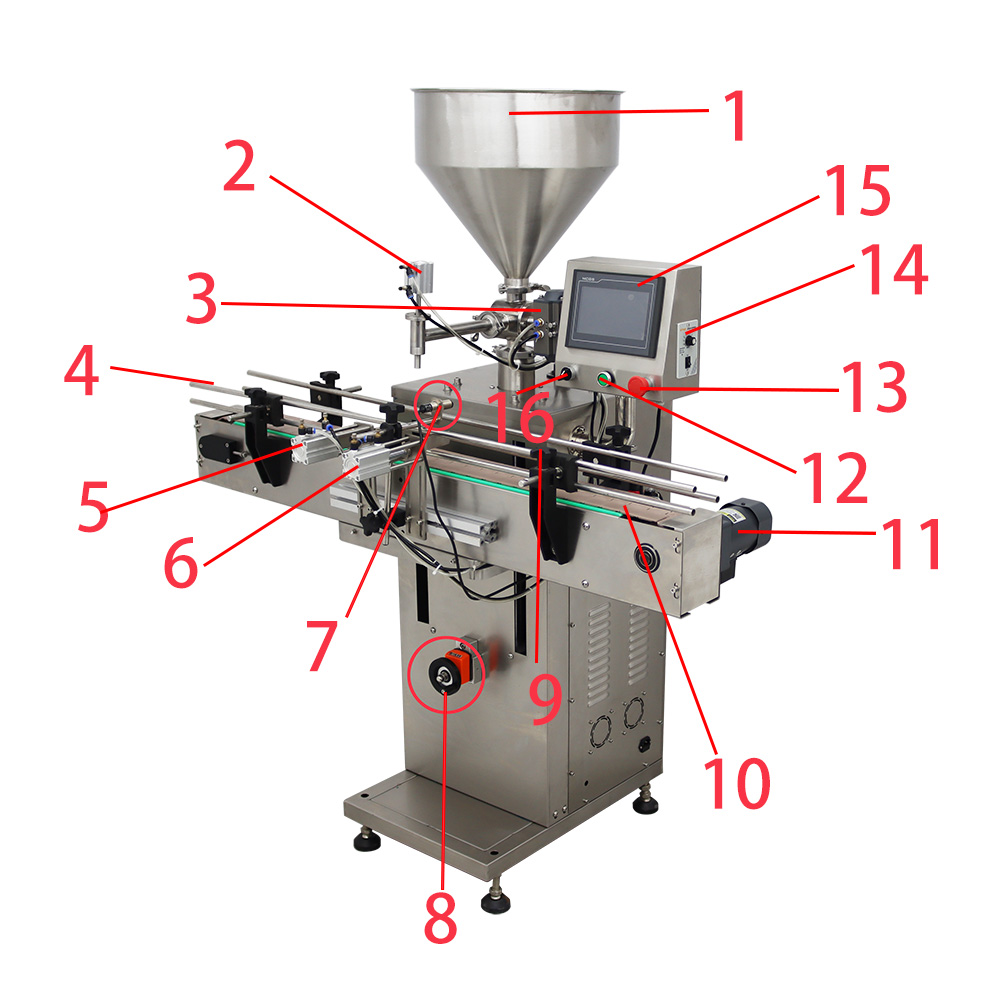

Product analysis: |

|

|

1. Hopper

2. Filling

assembly

3. actuator

rotary valve

4. Conveyor

belt protective fence

5. Blocking

cylinder

6. Positioning

cylinder

7. Light eye

(bottle measuring sensor)

8. Adjusting

the handwheel (adjusting the overall height of the conveyor belt)

9. Conveyor

belt adjustment knob

10. Conveyor

belt

11. Conveyor

belt motor

12. Start

switch

13. Emergency

stop switch

14. Conveyor

speed regulator

15. Touch

screen (human-machine interface)

16. Switching

power supply

|

|

|

|

Note:These two styles are shipped

randomly (with identical functionality). |

|

Product

safety precautions: |

|

To ensure production

safety, pay attention to the following:

1.If overflow occurs at the injection nozzle, press the safety emergency

stop switch to ensure the cleanliness of the workshop.

2. When disassembling and washing this machine, do not directly rinse

the body with water.

3. The air circuit of this machine must not be plugged or unplugged

arbitrarily.

|

|

Precautions for product use: |

|

1.The body of this

machine is made of stainless steel, please do not use sharp or hard

tools to scratch its surface.

2. The cylinder has been lubricated before leaving the factory. Please

do not open the cylinder or add any lubricating oil.

3. Cleaning

requirements:

When cleaning, it is important to ensure that the piston sealing ring is

properly installed. Turn on the machine and let it cycle filling until

it is clean. This cleaning is relatively simple and can be used in

situations with low requirements. In high demand situations, all

components that come into contact with the material should be thoroughly

cleaned, including the material cylinder, piston, piston sealing ring,

three-way valve, filling head, feed pipe, discharge pipe, etc. When

cleaning all sealing rings, it should include the sealing rings of the

piston and the flat sealing rings of the valve, and replace the broken

and damaged sealing rings.

|

|

Details: |

|

|

|

|

|

|

|

Advantages:

|

|

1. This machine has an intelligent touchable operation

screen, which is more convenient and fast for processing work.

2. One touch operation, convenient and simple.

3. The bottles stacked on the conveyor belt can be

separated one by one, without artificial deliberate placement, saving

manpower.

4. The chain plate conveyor belt has a longer

service life than the ordinary belt. It can automatically transport

products, saving time and labor.

5. Imported motor, lasting and durable, strong

power.

|

|

Product display: |

|

|

|

|

|

|

Item include:Single

head automatic servo paste liquid dual purpose filling machine*1 |

|

Item Number: 160196 |

|

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|