|

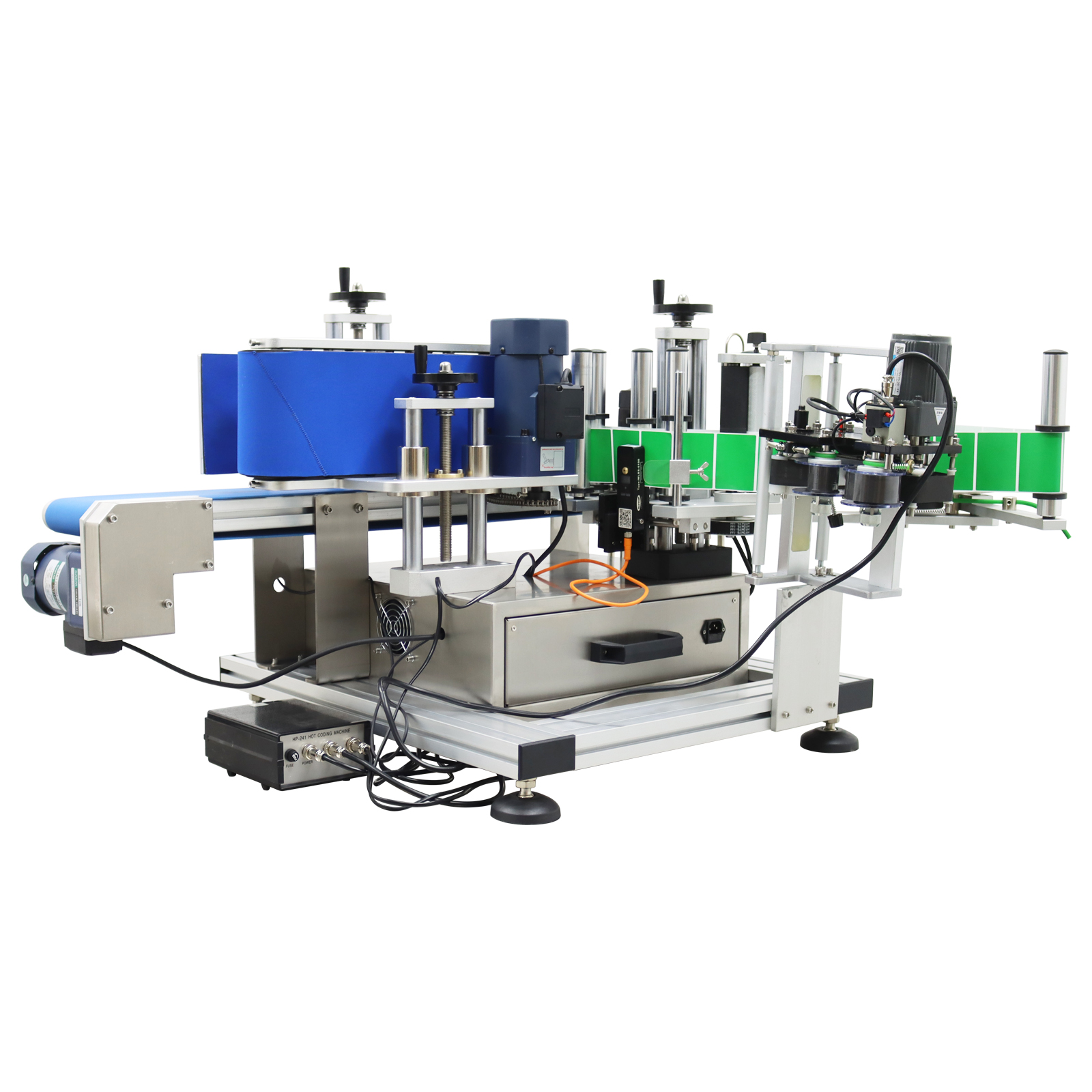

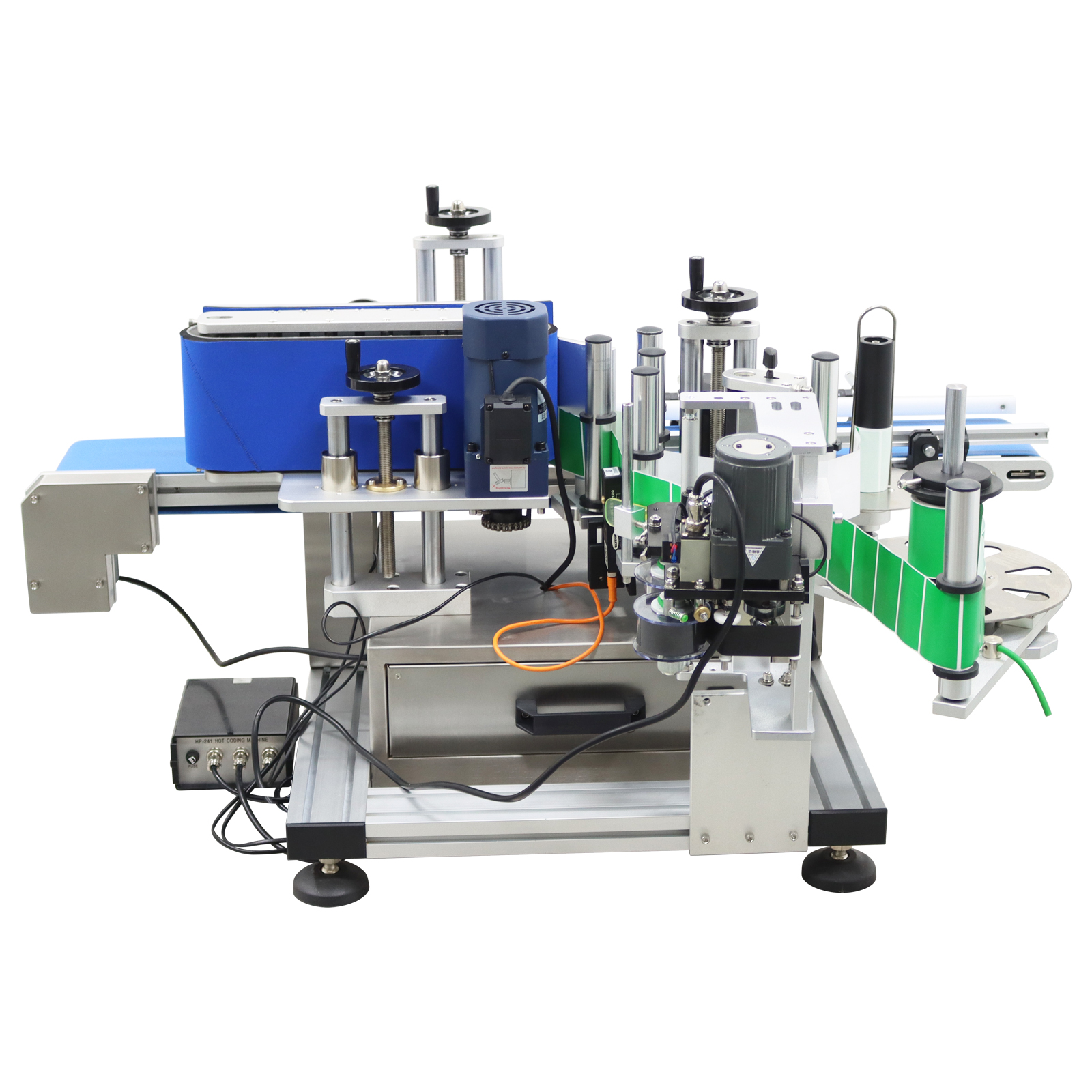

LT-150D Automatic

Desktop Conveyor Table Round Bottle High Speed Marking And Labeling

Machine |

|

The

machine is beautiful, smart, and has a high qualification rate. It is

suitable for labeling in cosmetics, beverages, medicine,

food, general merchandise and other industries.

The design of the machine is novel and unique, and the operation and

adjustment are very convenient. The operator only needs to place the

bottle on the conveyor belt,when the bottle moves forward, the cursor

will automatically label and mark the bottle after detecting it.

It can be used for both stand-alone production and online production. |

|

|

|

Product parameter: |

|

|

Voltage: |

110V/60Hz |

|

Material: |

The

surface is stainless steel |

|

Conveyor width:

|

5.9in(15cm) |

| Conveyor belt length: |

45.86IN(116.5CM) |

| Label inner diameter: |

2.99in(7.6cm) |

| Label outer diameter: |

9.8in(25cm) |

| Label out: |

Left bid |

|

Output speed: |

20-200PCS/min (Depending on

the bottle size and label length) |

| Suitable bottle diameter: |

1.57-3.9in(4-10cm) |

|

Label height: |

0.59-5.9in(1.5-15cm) |

| Label length: |

0.98-11.8in(2.5-30cm) |

| Label Type: |

Full label, regular label, hot stamping,

silver stamping, fully transparent label. |

| Precision: |

±0.039in(1mm) |

|

Package: |

Export wooden case |

|

|

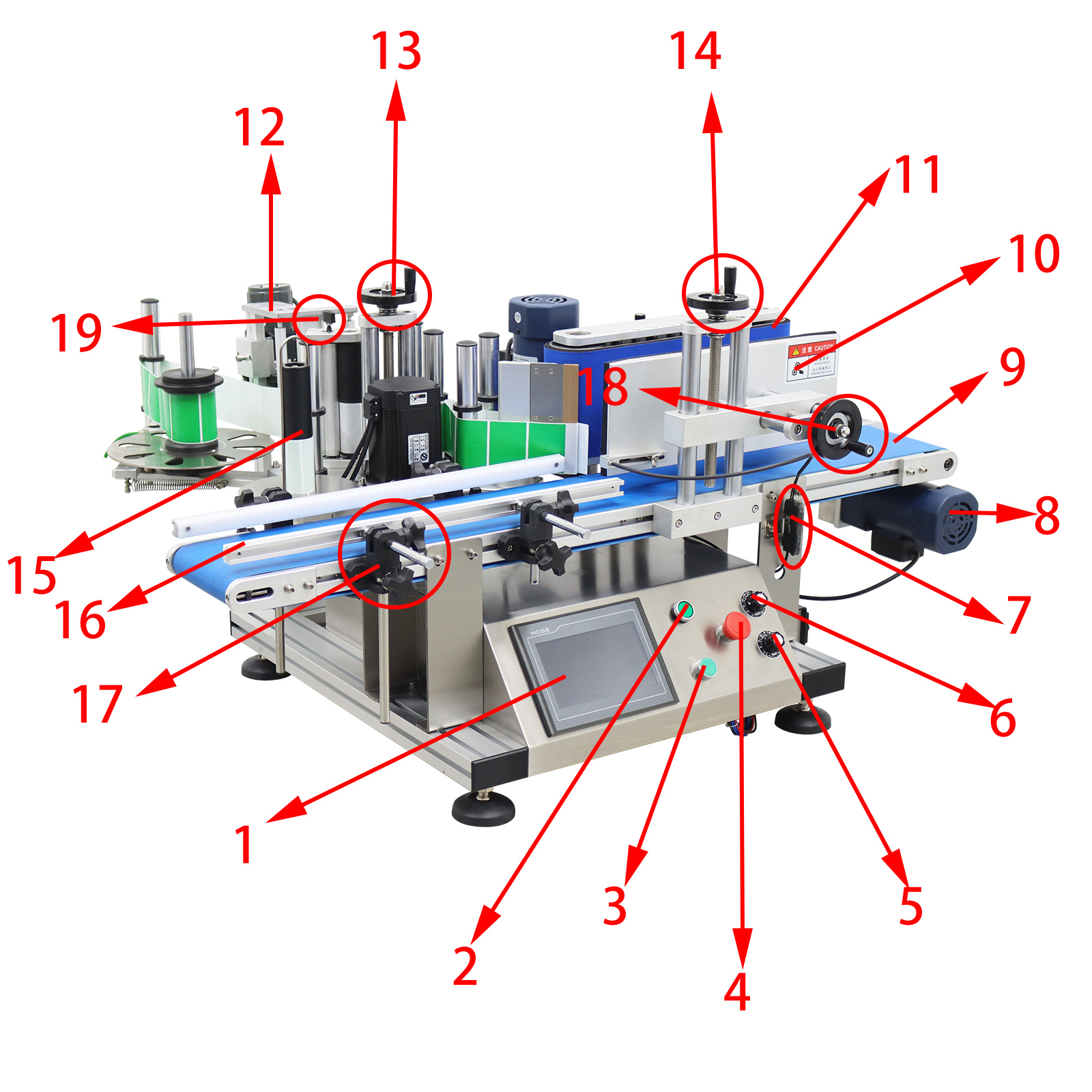

Product Analysis: |

|

|

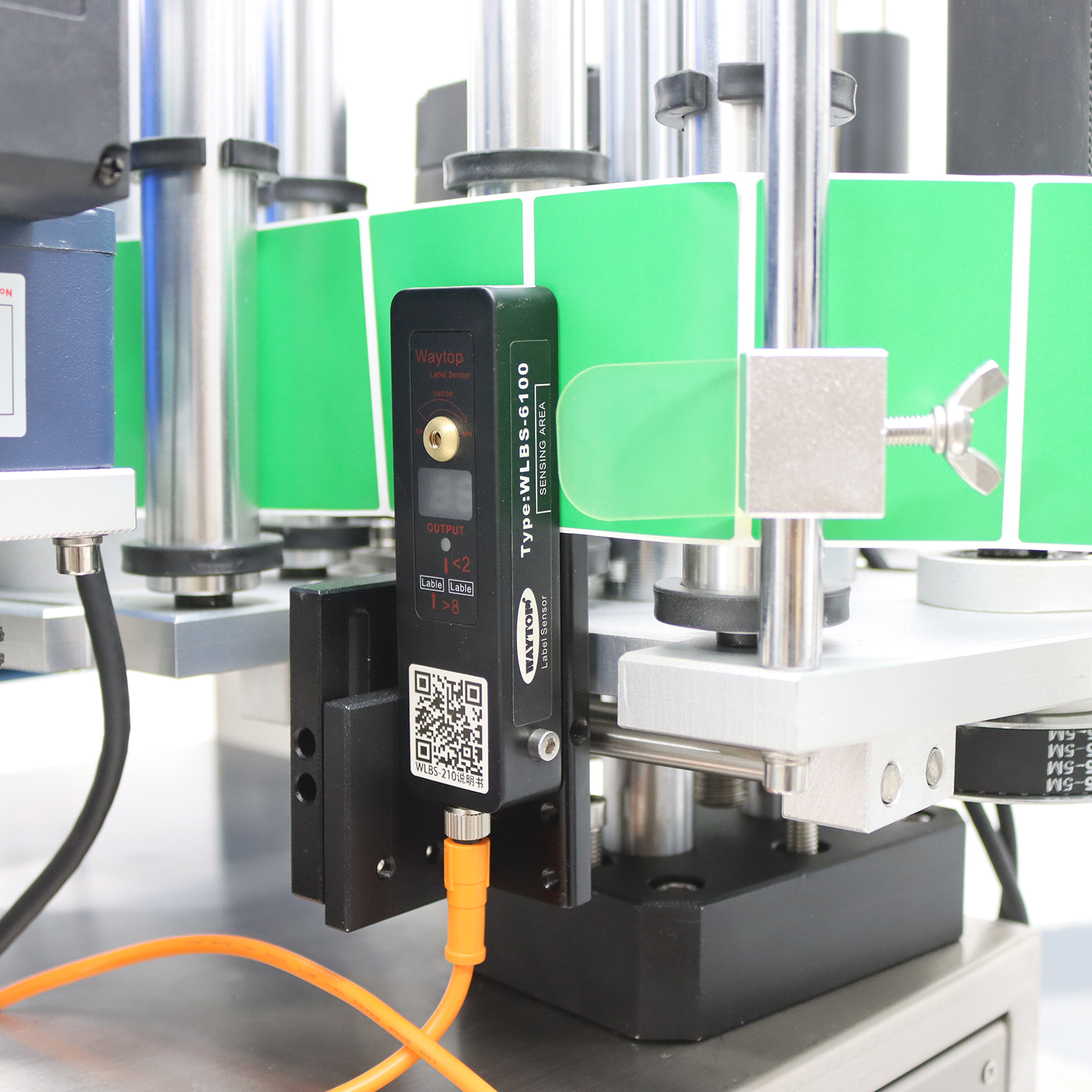

1. Intelligent

control panel

2. power switch

3. Start key

4. Emergency

stop switch

5. Spoke speed

control knob

6. Transmission

speed control knob

7. Label sensor

8. Conveyor belt

motor

9. Conveyor belt

10. Wheel

auxiliary pressure plate

11. Wheel

auxiliary belt

12. Coding

machine

13. Labeled

assembly lifting hand wheel

14. Wheel

auxiliary pressure plate lifting hand wheel(Wheel auxiliary pressure

plate lifting handwheel Adjust clockwise to raise the wheel auxiliary

pressure plate)

15. Receiving

drum

16. Guardrail

17. Guardrail

adjusting knob

18. Front and

rear adjusting hand wheel of wheel auxiliary pressing plate(Front and

rear adjusting hand wheel of wheel auxiliary pressing plate.)

19.One character handwheel |

|

Feature: |

|

|

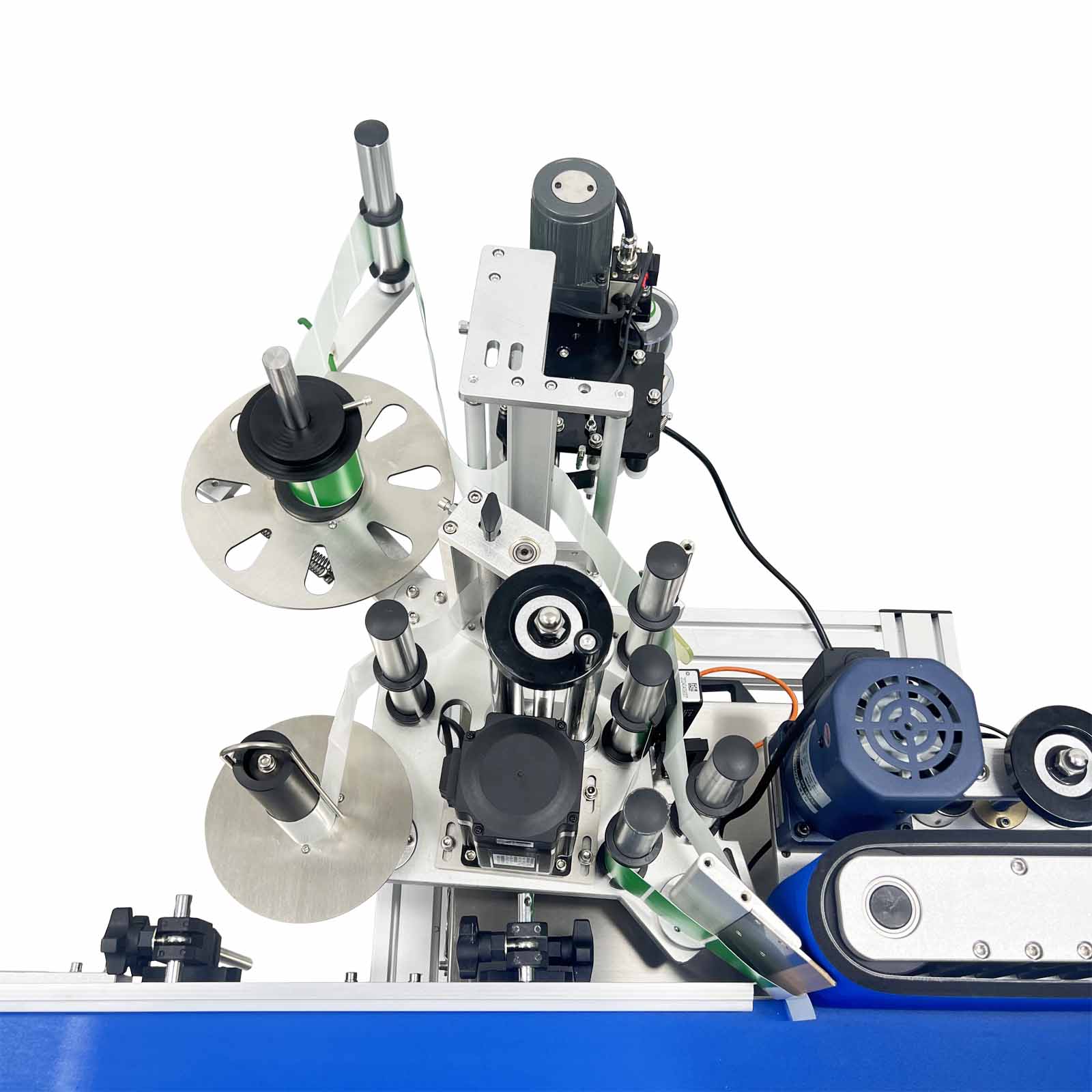

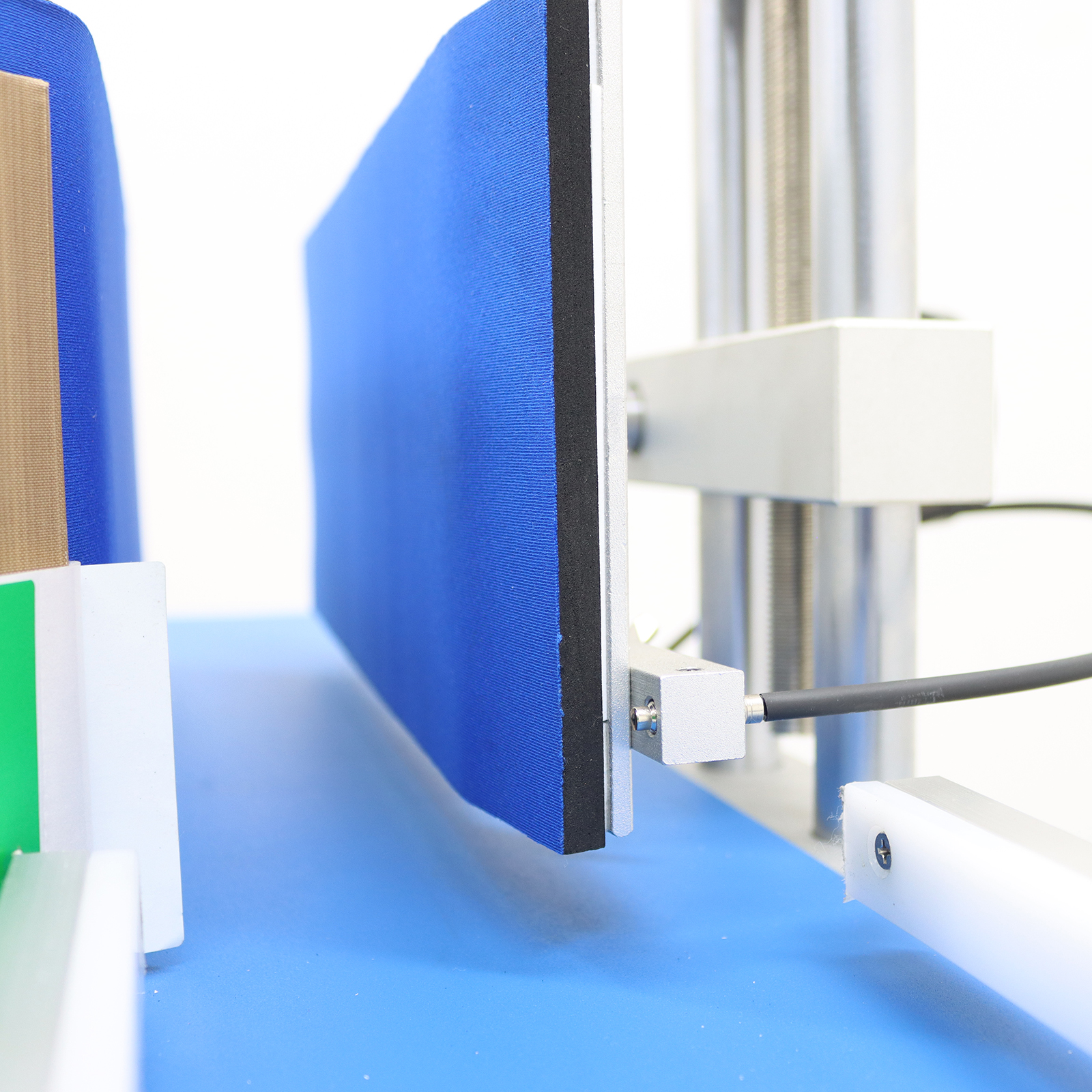

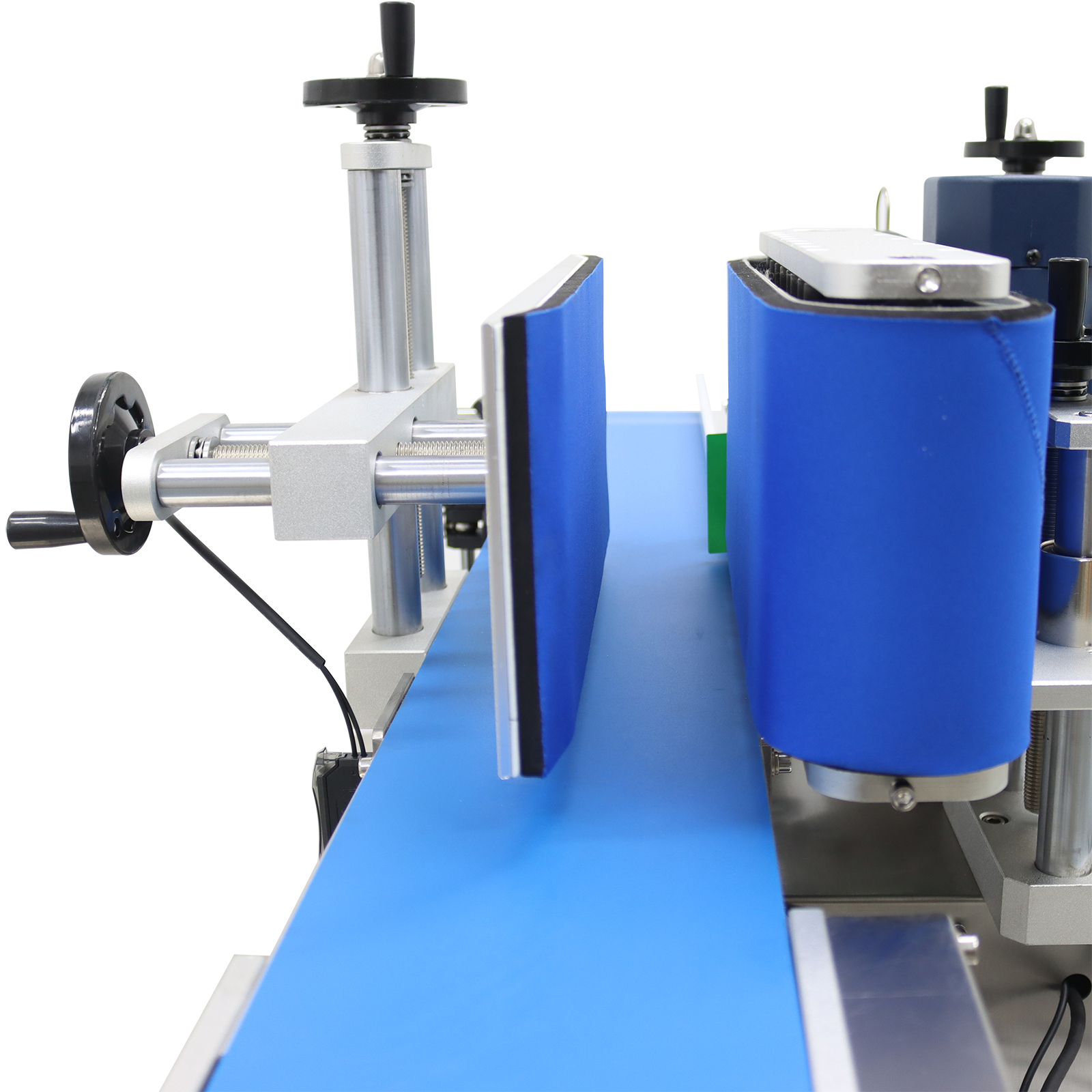

Multi-rod spiral positioning prevents

deviation and makes the sheet more accurate. |

|

Rubbing type label

Add rolling-type labeling to

effectively solve the bubbles duringproduct labeling, and the labeling

isflat without wrinkles. |

|

|

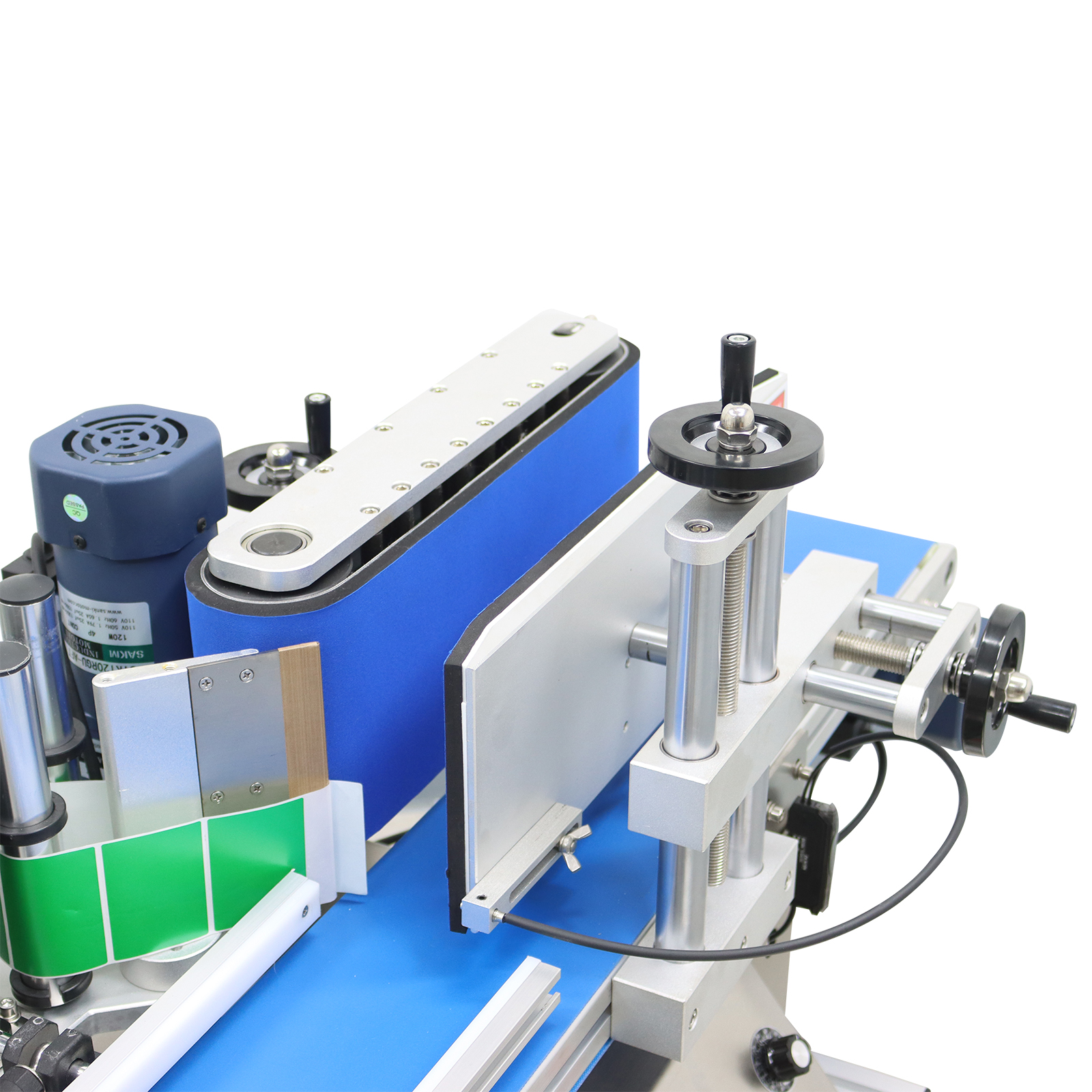

Spoke adjustment handle

Adjusting the two handles clockwise can move the spoke pressure plate

forward and upward. |

|

The label object is sensitive to

inspection, and the labeling efficiency is greatly improved.

This machine is a universal sensor that

can sense ordinary labels, as well as hot stamping, silver stamping, and

fully transparent labels, with stronger functionality. |

|

|

|

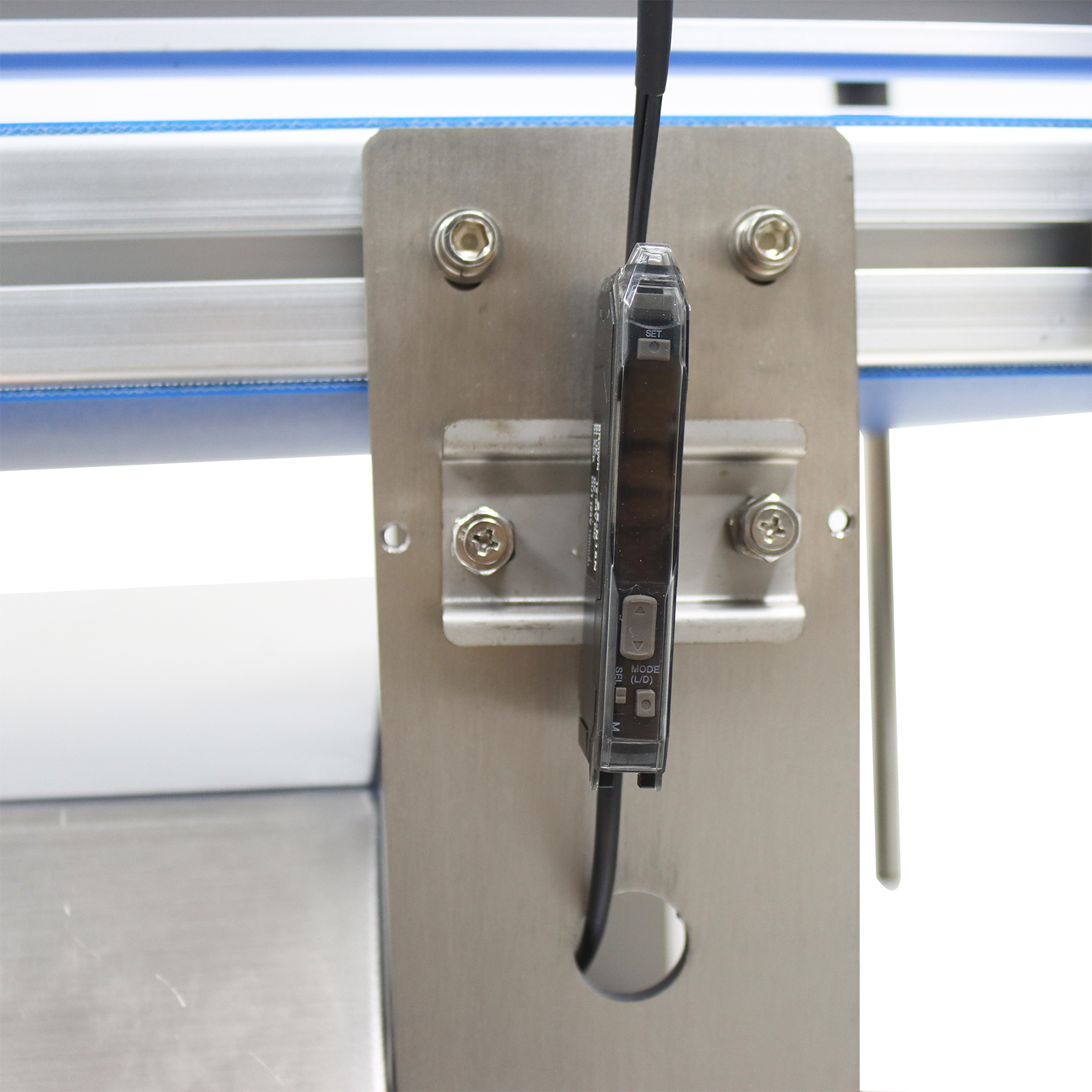

Photo-electric detection label, and the

label will be released immediately when the bottle is detected to pass. |

|

This machine is equipped with a fiber

optic amplifier, which can be adjusted by adjusting the fiber optic

amplifier when the photosensitive eye cannot sense the product well.

|

|

|

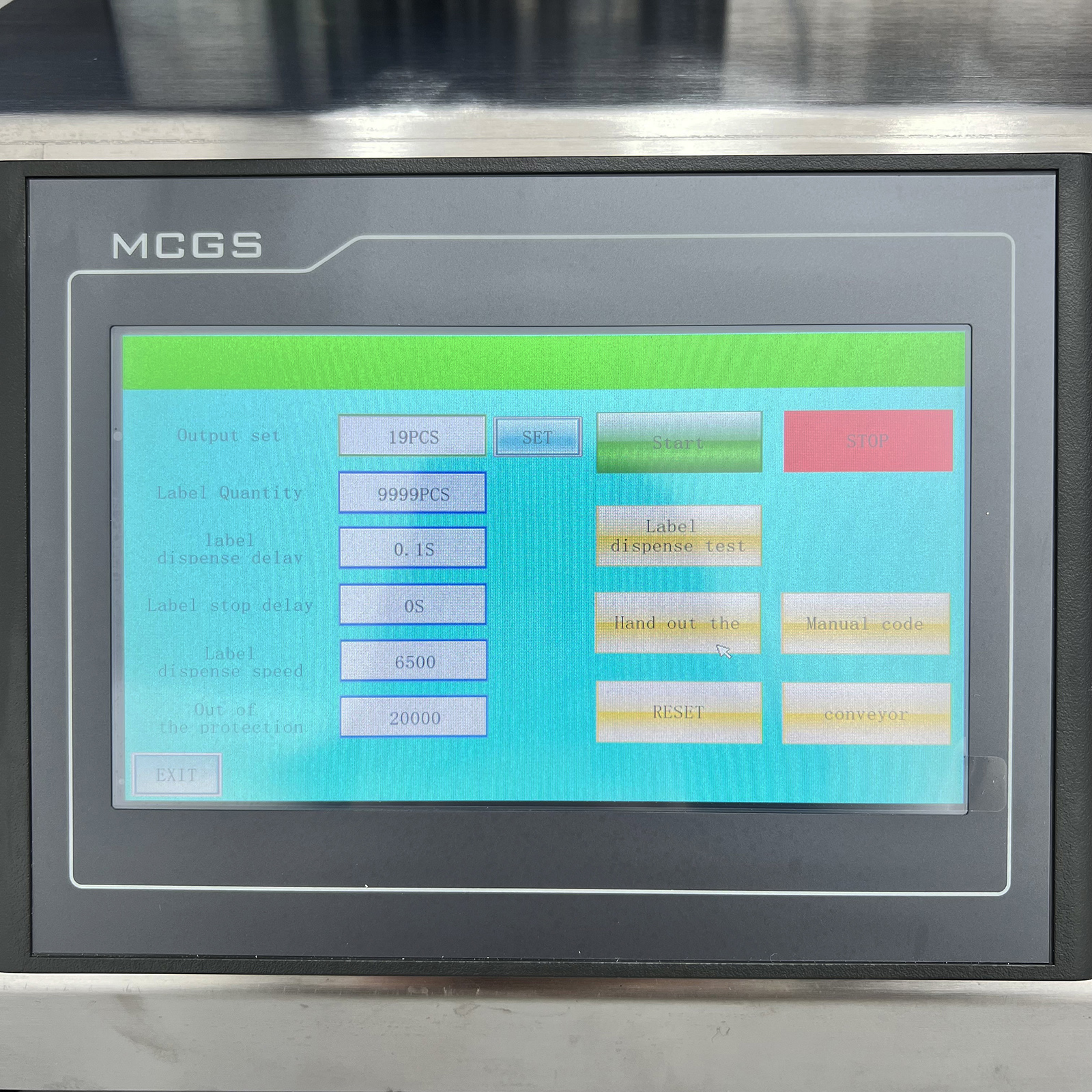

This machine is equipped with a touch

screen display, which allows customers to set relevant data according to

their needs, making it more convenient and efficient. |

|

This machine is equipped with an

emergency stop button, which can stop the operation of the machine with

one click in case of any emergency, making it safer and more reliable. |

|

|

This machine is equipped with a

high-quality conveyor belt motor, which is more durable. |

|

This machine is equipped with a belt

conveyor for better product transportation. |

|

|

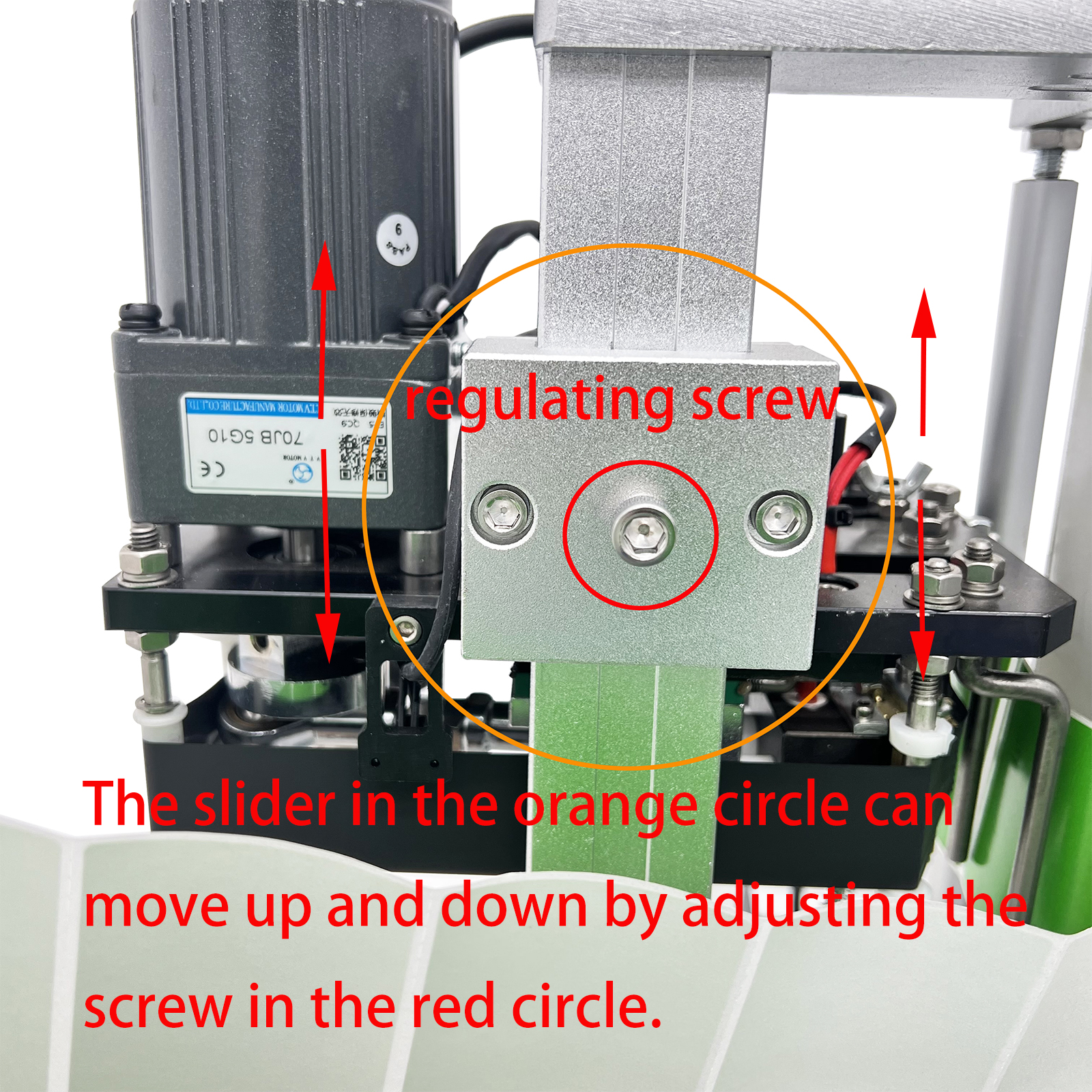

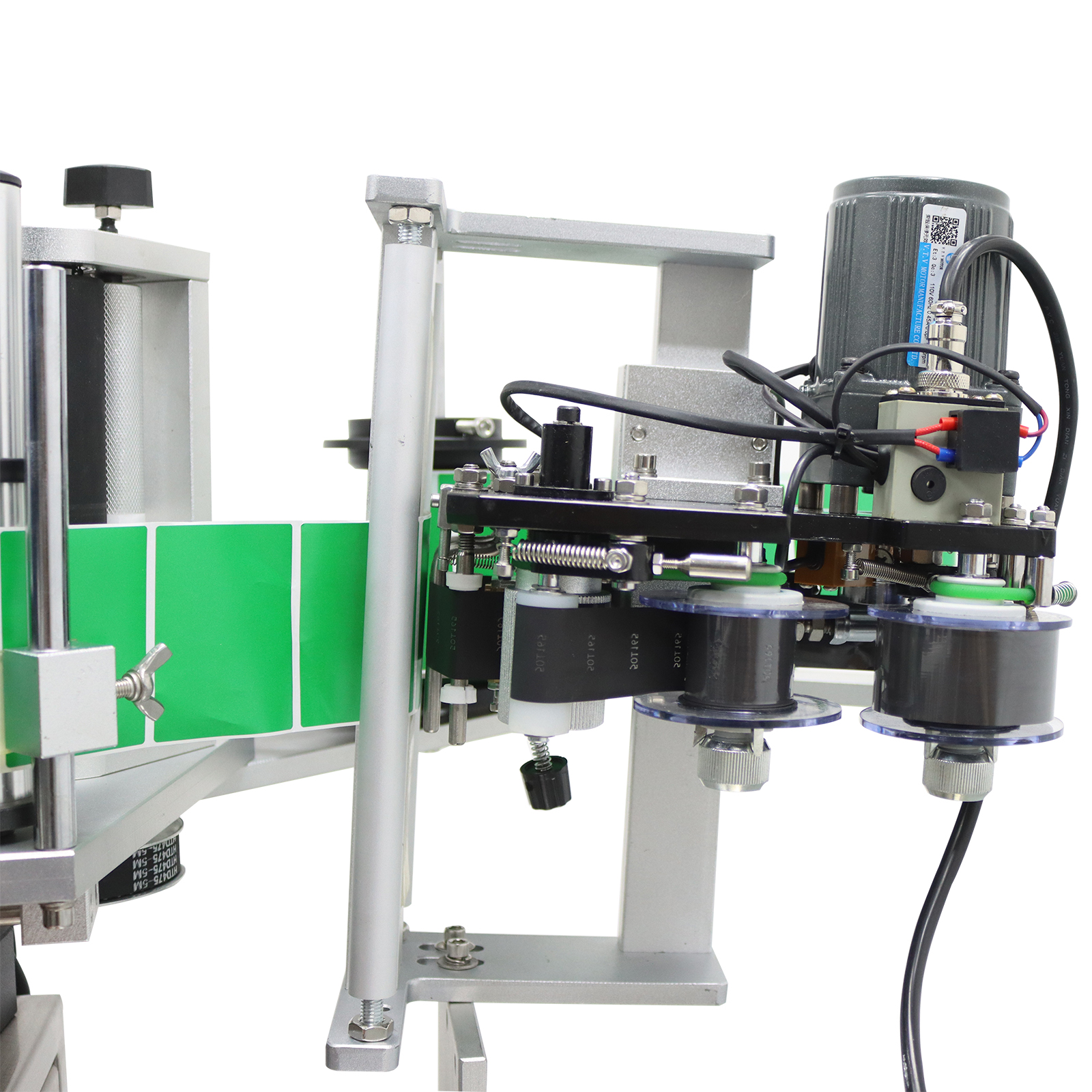

The slider in the orange circle can be

moved up and down by adjusting the screw in the red circle, and

customers can adjust the appropriate position of the coding machine

block as needed. |

|

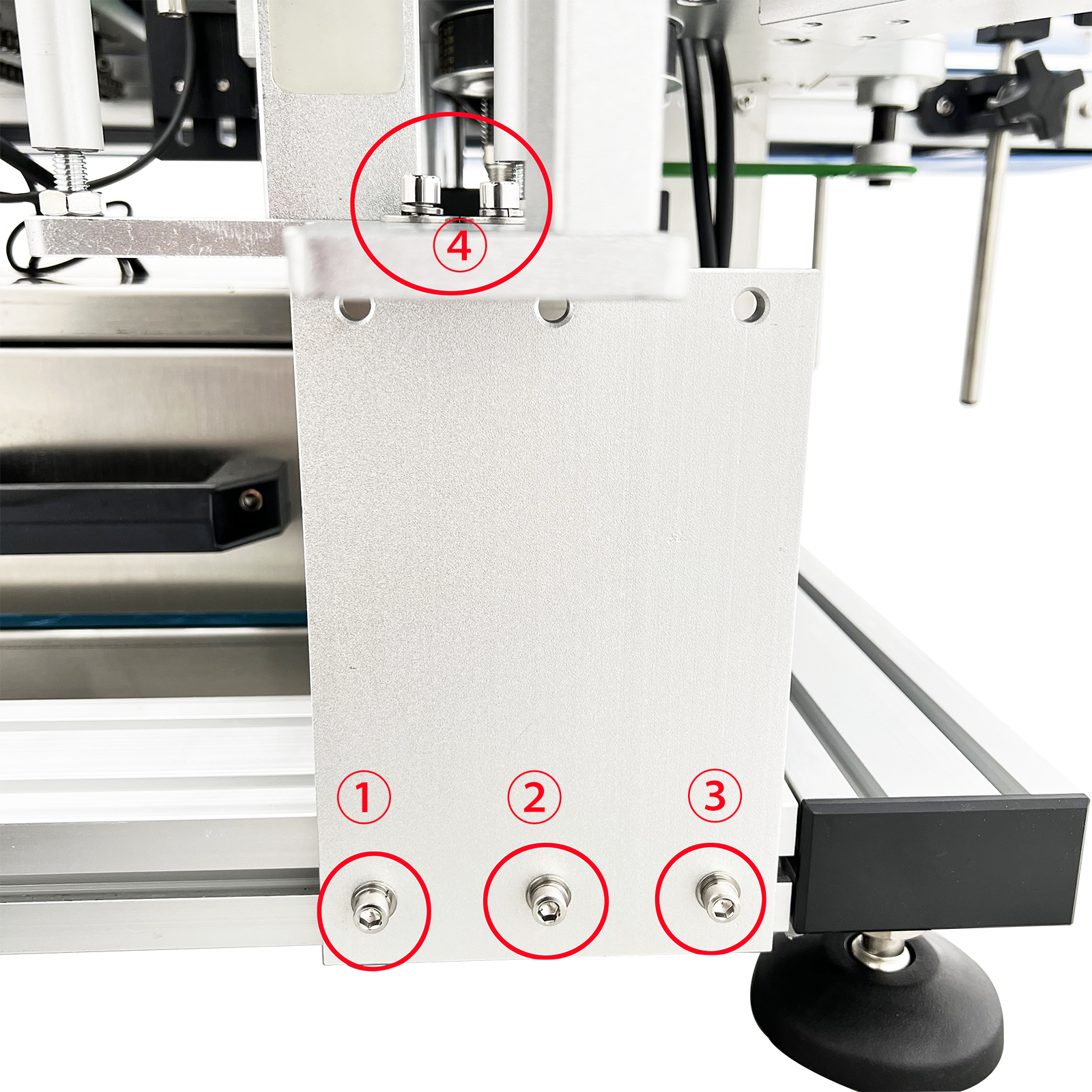

①②③Screw is fixed on the casingframe

and can be moved accordingto the customer's needs;The④screw is used to

fix the printer. |

|

|

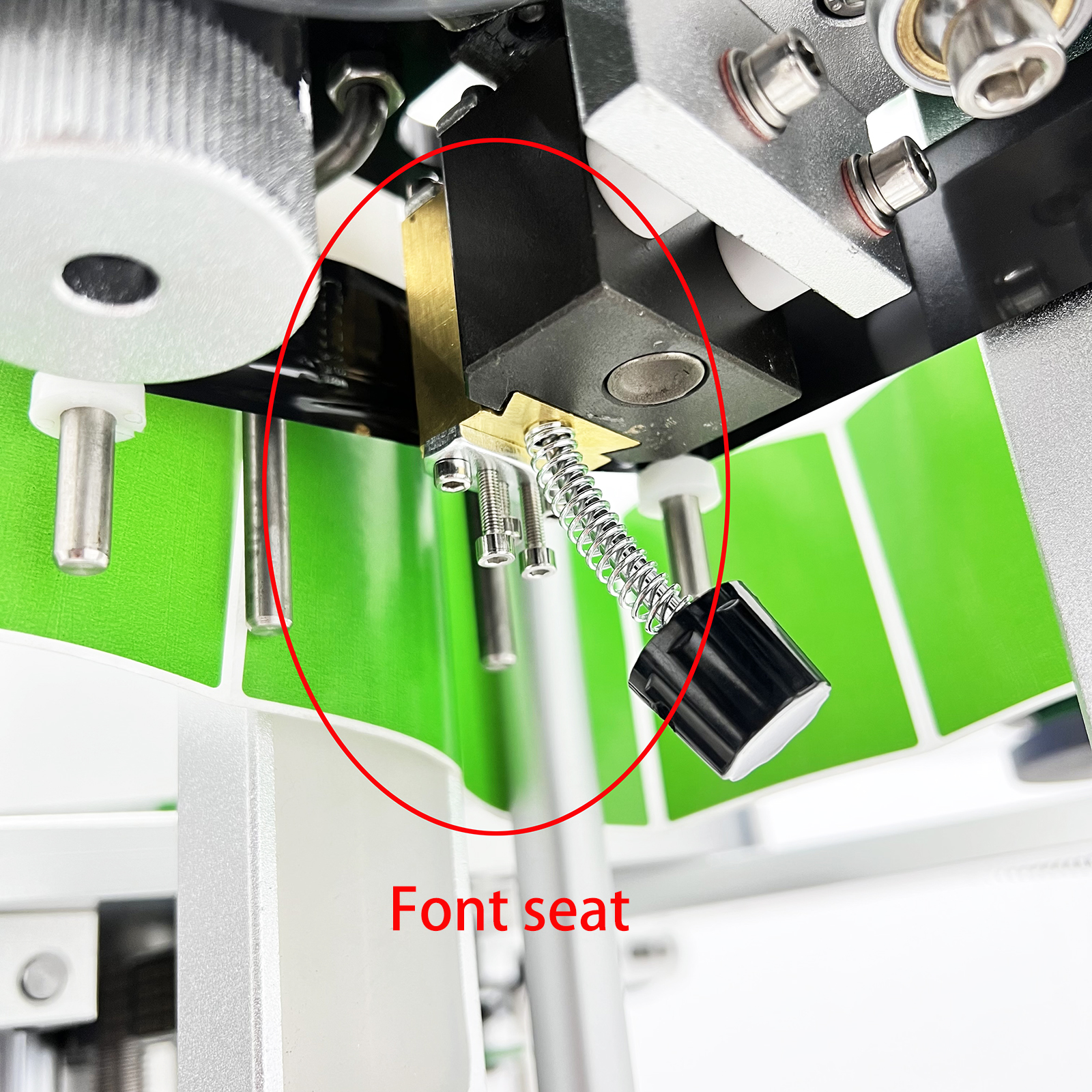

Print block The word to

be printed is placedin the word seat to realize theprinting function.(There

are only 9 English letters, namely exp, lot, and mfg, used for coding.

The abbreviation includes the production date, product batch number, and

expiration date. Each English letter contains 5 letters, with the

numbers 0, 1, and 2 being the same 5 letters and the remaining numbers

being the same 3 letters.) |

|

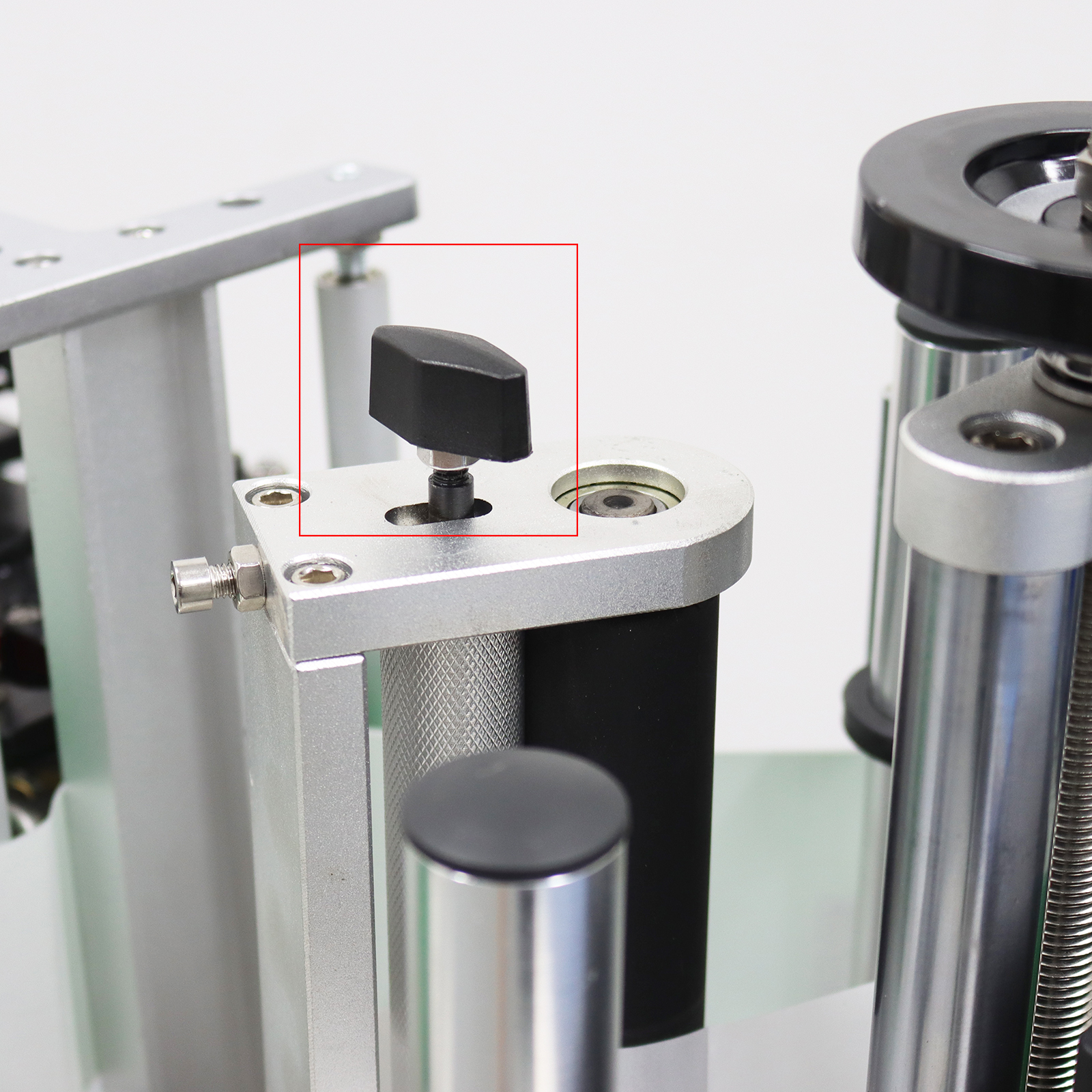

After correctly putting on the label,

be sure to tighten the one character handwheel and hear a click. |

|

|

|

Customers can adjust the distance of

the guardrail according to the diameter of the bottle, and the distance

of the guardrail is adjusted by adjusting the knob. |

|

Product

safety precautions: |

To ensure safe production, please read the

following precautions carefully:

1. Use the power supply that meets the requirements of the machine.

2. After turning off the power switch, there is still voltage in some

circuits in the electrical control of the machine. When servicing the

control circuit, be sure to unplug the power cord.

3. Do not touch the rollers with your hands during machine operation,

and pay attention to personal safety.

4. When the machine has problems, press the emergency stop button

directly to suspend all work.5.Do not

touch the photoelectric induction eye with your hands during machine

operation to prevent the machine from missensing and mislabeling.

|

|

Details: |

|

|

|

|

|

|

|

|

Advantages:

|

|

1. The machine is efficient and convenient to use;

2. The machine automatically labels, saving manpower and material

resources;

3. This machine has wide applicability and stable performance;

4. This machine is equipped with intelligent touch control screen, which

is more convenient to set data parameters;

5. This machine can meet the

requirements of non 360 degree full circle labeling for round bottles.

The label switching between bottles is very simple, with smooth and

wrinkle free labels, improving packaging quality.

6.This machine can be used with capping machine and bottle sorting

machine.

7.The components of each adjustment position are precisely matched, and

the height, width and width of the components can be easily adjusted

without the use of professional tools. The machine operation is simple

and simple.

|

|

Product display: |

|

|

|

|

|

|

Item include:LT-150D

Automatic Desktop Conveyor Table Round Bottle High Speed Marking And

Labeling Machine*1 |

|

Item Number: 160309 |

|

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |