|

|

|

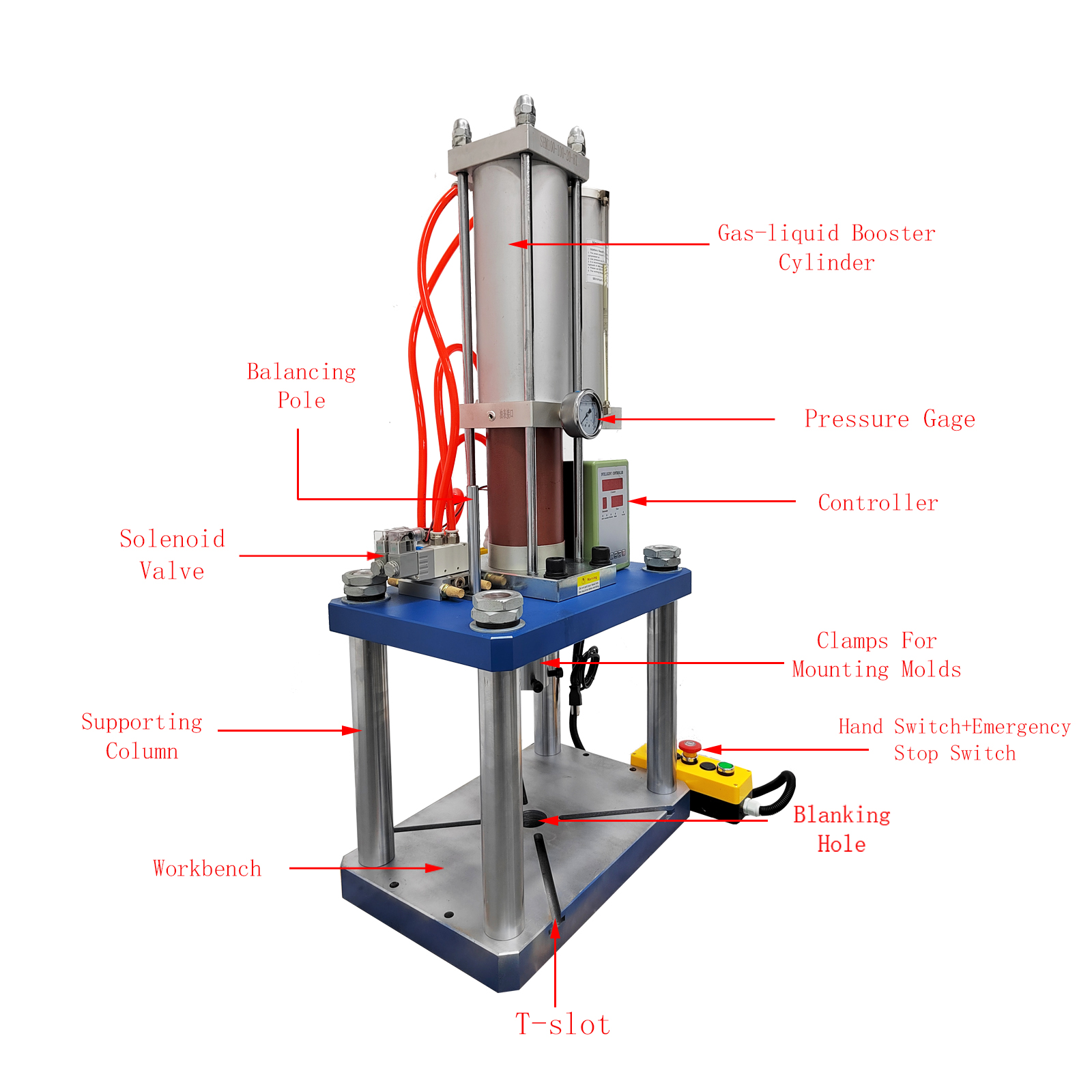

17636Lbs/8000kg Pneumatic Punch

Machine |

|

|

|

Product Features: |

|

The pneumatic press is the high-pressure

gas produced by the compressor, which is transported to the

solenoid valve through the gas pipe. The working state of the cylinder

is controlled by the movement of the solenoid valve through the switch,

and the punching is completed.

1 .Compressed air as power source, high efficiency

and easy operation, can reduce labor, can be applied to manual operation

integration, automated assembly line .

2 .Simple structure, convenient operation, cheap price, superior

performance, no noise produced during the hydraulic system and electric

standby, can save electricity consumption reduce production cost, has

the very high cost

performance .

3. Easy adjustment of output, need to adjust the air pressure is

adjustable up to the required pressure, high yield .Equipped with guide

plate, high accuracy, can adapt to high speed precision impact load .

4.According to different products or mould, adjust the speed, and the

size of the pressure and stamping time .

5.Optional manual switch control, with emergency stop switch, can also

be controlled by a controller.

6.Microcomputer control system, can choose manual, semi- automatic and

fully automatic operation. |

|

Specification : |

|

Voltage |

110V |

|

Pressure |

17636lb/8000kg |

|

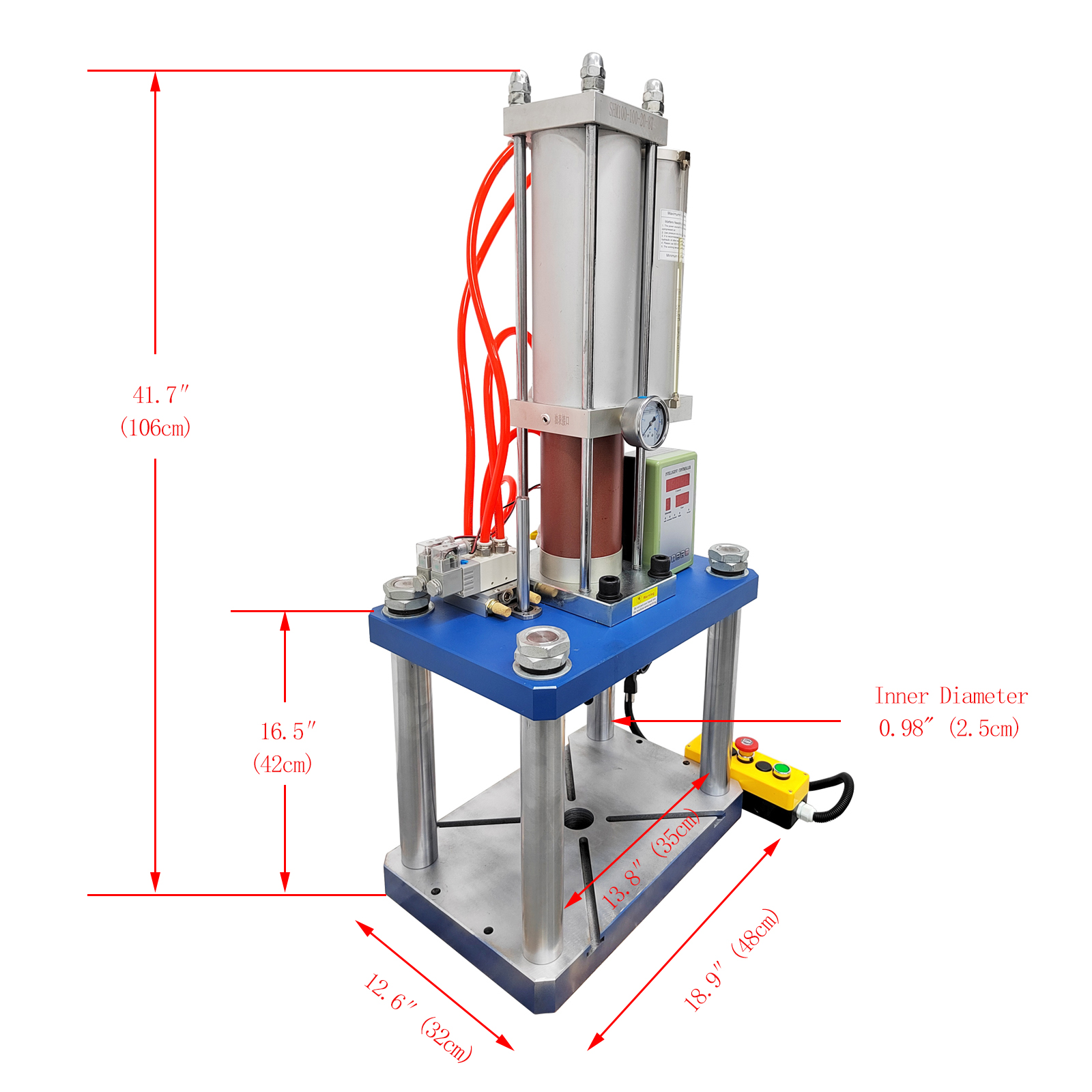

The die hole diameter |

0.98inch/2.5cm |

|

Working Countertops Size |

18.9*12.6inch/48*32cm |

|

Outer diameter of trachea |

0.47inch/1.2cm |

|

Booster cylinder specification |

3.94inch-0.59inch/100mm-15mm |

|

Working

air pressure |

0.5-0.8MPa |

|

|

|

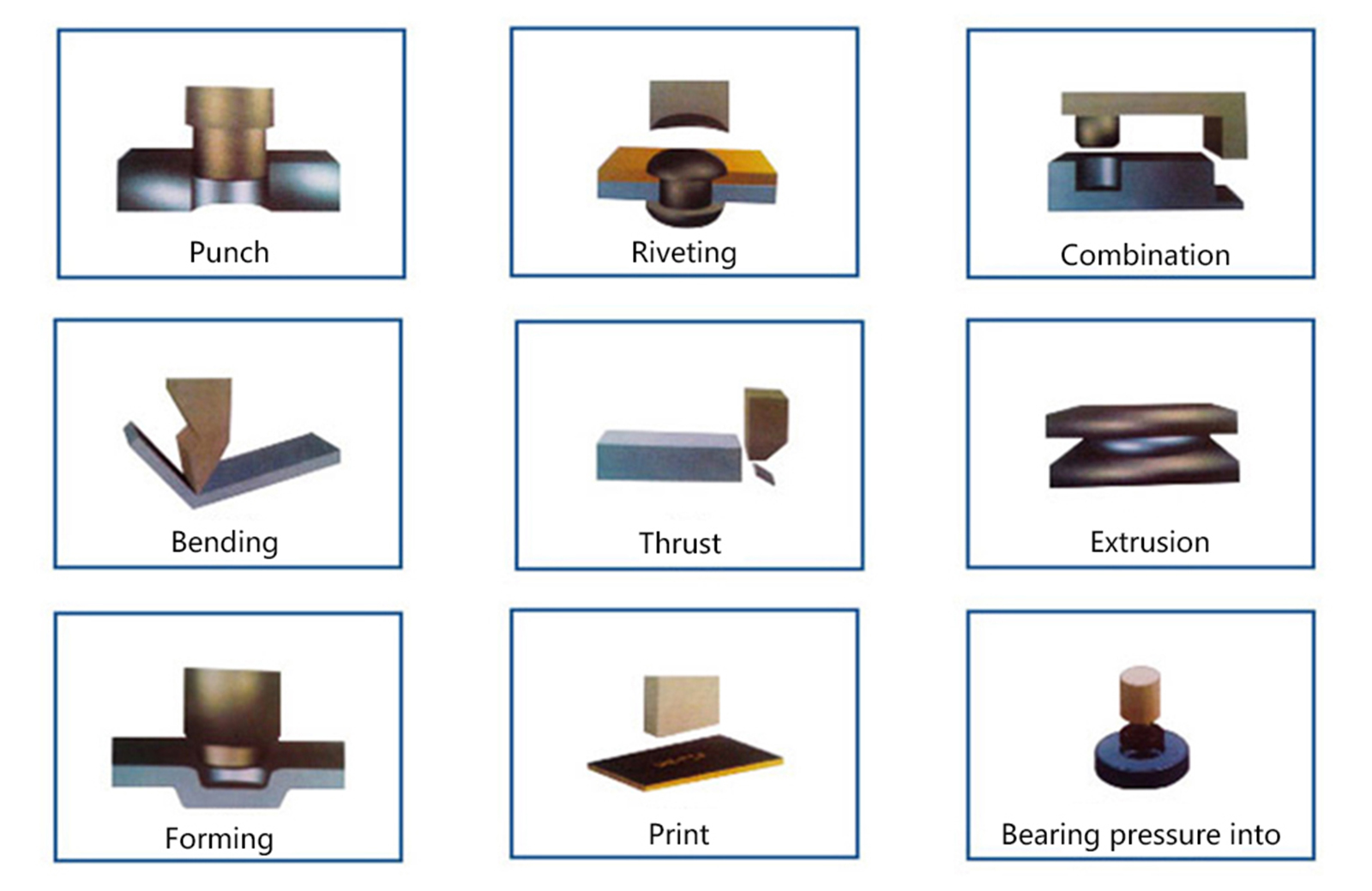

Range of application: |

Suitable for electronics,

electrical appliances, instruments, meters, cameras, watches, jewelry,

hardware

and garment, shoes and hats. |

|

|

Machinable materials: |

| For sheet, strip, coil to

shear, punching, blanking, forming, bending, riveting, etc;Suitable for

non-ferrous metal, plastic parts processing . |

|

Detail: |

|

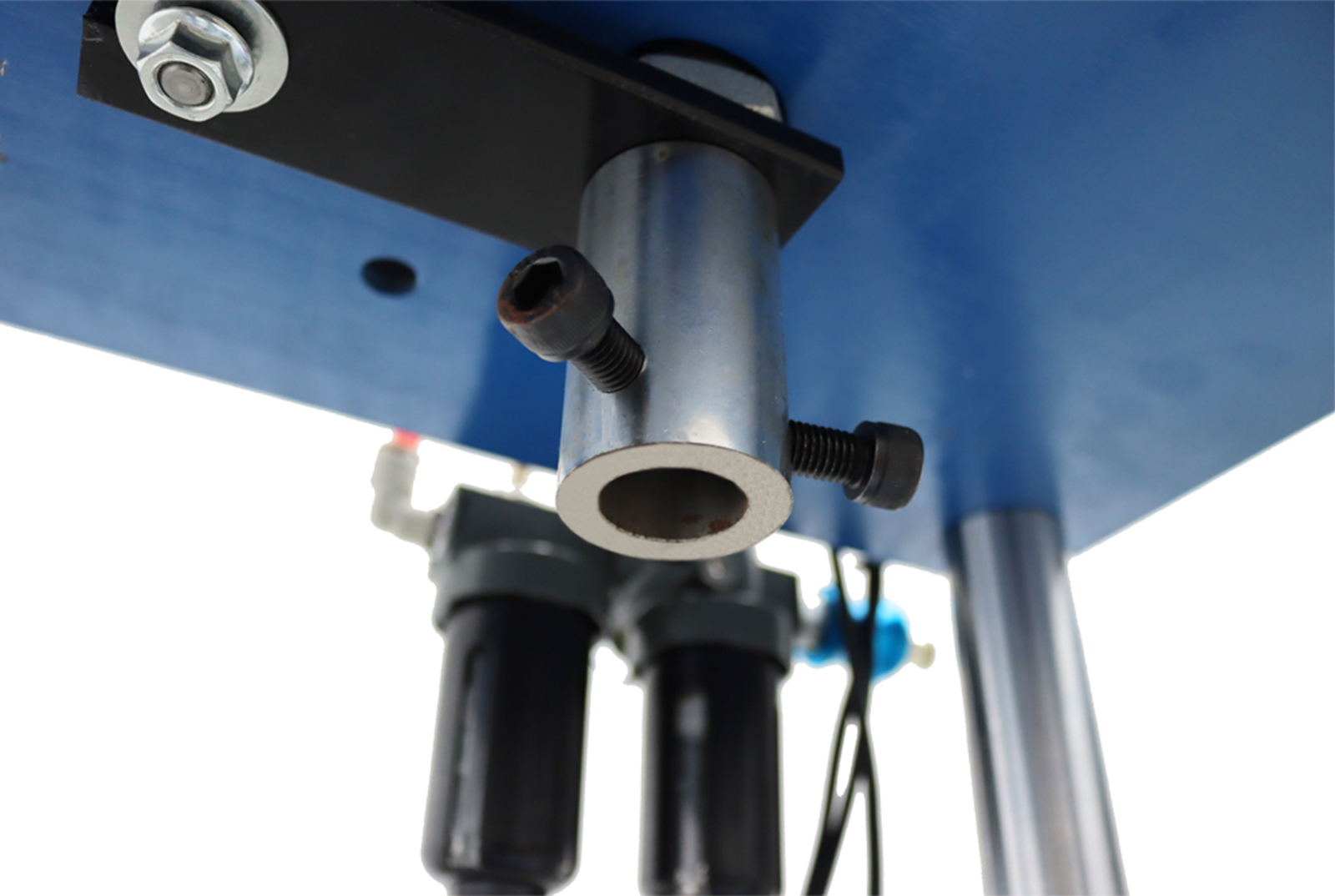

Air source processor, through the pressure gauge at

any time to observe the change of air source pressure, effective

separation of water, oil and other impurities in the air, air

purification, improve the service life of the machine. |

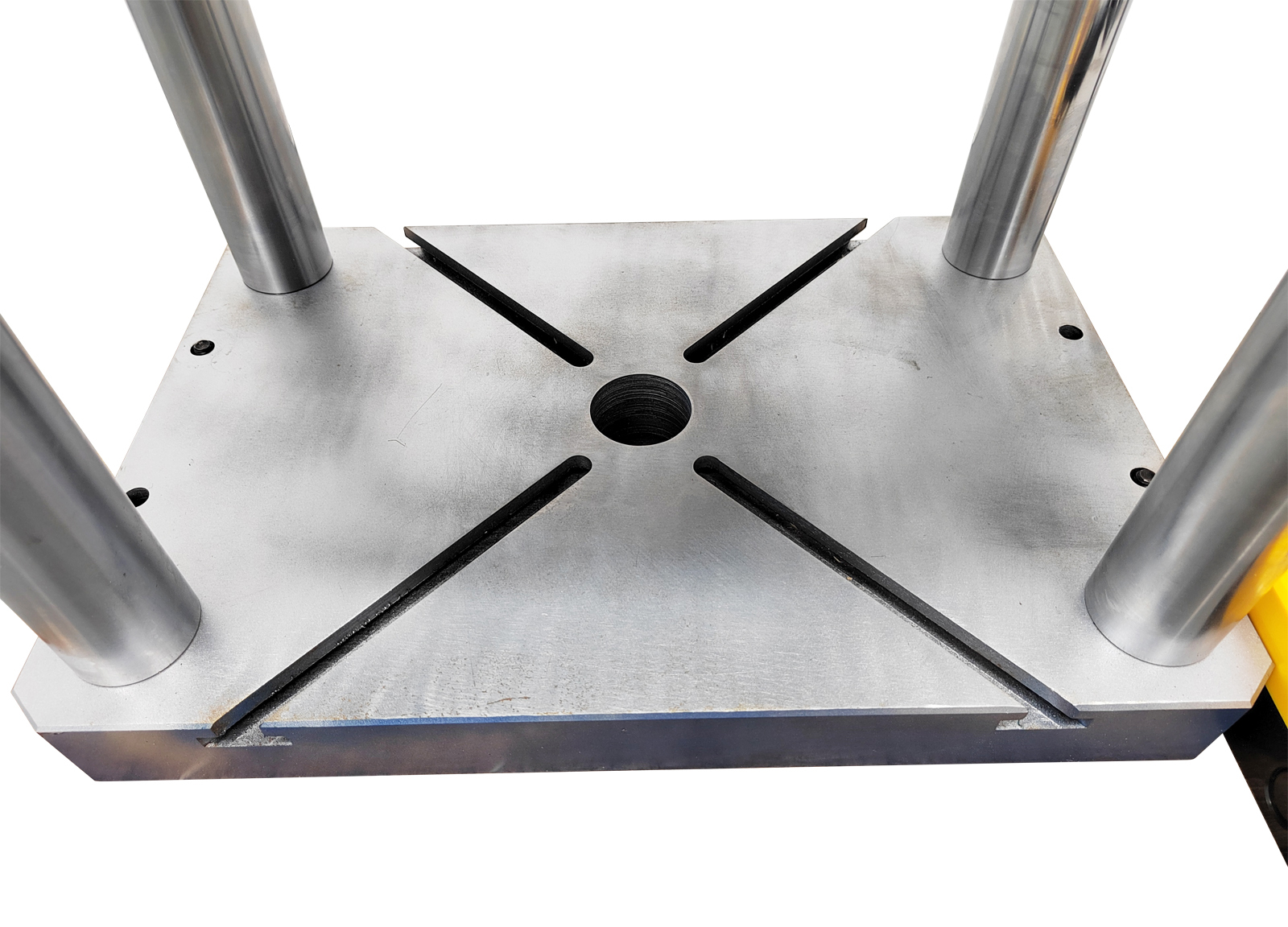

| Widened and enlarged work surface with 1.9 "diameter

blanking hole, 4 T-slots for easy securing of items. |

|

|

A clamp with an inner diameter of 0.98 ", equipped

with a guide plate, is more precise and stable. |

| Two-handed switch, two-handed operation, safer.

Equipped with emergency stop switch, one key stop, more efficient. |

|

|

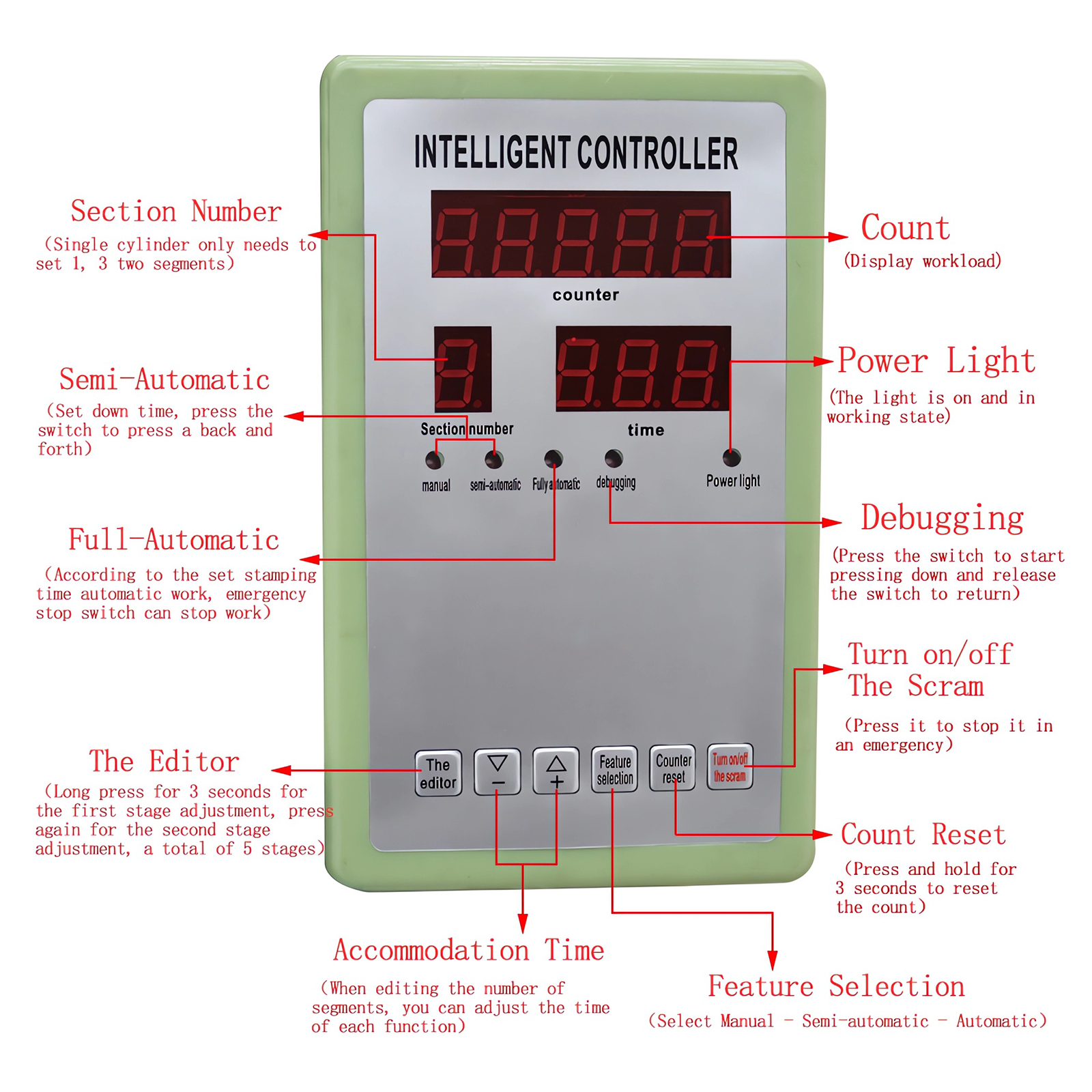

Equipped with a controller, easy to switch between

manual operation and automatic operation .(single cylinder machine, just

set 1, 2, 3 section number. 1 is the pressing time setting; 2 is the

second time to increase the setting; 3 is the return time setting) |

|

Note: 1. 46# antiwear hydraulic oil should be added to

the hydraulic cylinder. It is recommended to replace the hydraulic oil

after one year of use. (Due to ex-factory debugging, there will be a

small amount of hydraulic oil in the machine, please prepare your own

hydraulic oil after receiving the goods).

2.Check whether the machine bolts are tightened before working. If

they are loose, they must be tightened before working.

Check whether the air pipe is properly connected to prevent air leakage

and make the machine unable to work normally.

3. Avoid placing your hand under the punching shaft during work to

avoid accidents .

4.Do not wipe the machine with a damp cloth to avoid rusting the

machine .

5.When disassembling, installing and adjusting the mold fixture, the

machine must be turned off, and standby operation is strictly prohibited

to avoid personal injury .

6.The rated pressure of the air compressor is 0.8mpa. The capacity of

the air compressor storage tank is about 60L,the larger the capacity,

the longer the service time and the more stable it is. The displacement

is optional 200L/min, the larger the displacement, the larger the

applicable machine model.

7.Note :The actual output pressure is about 80% of the theoretical

pressure. |

| Item Number:

17636Lbs/8000kg Pneumatic Punch Machine 230292 |

| |

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from

us with low cost. |

|