|

|

|

|

|

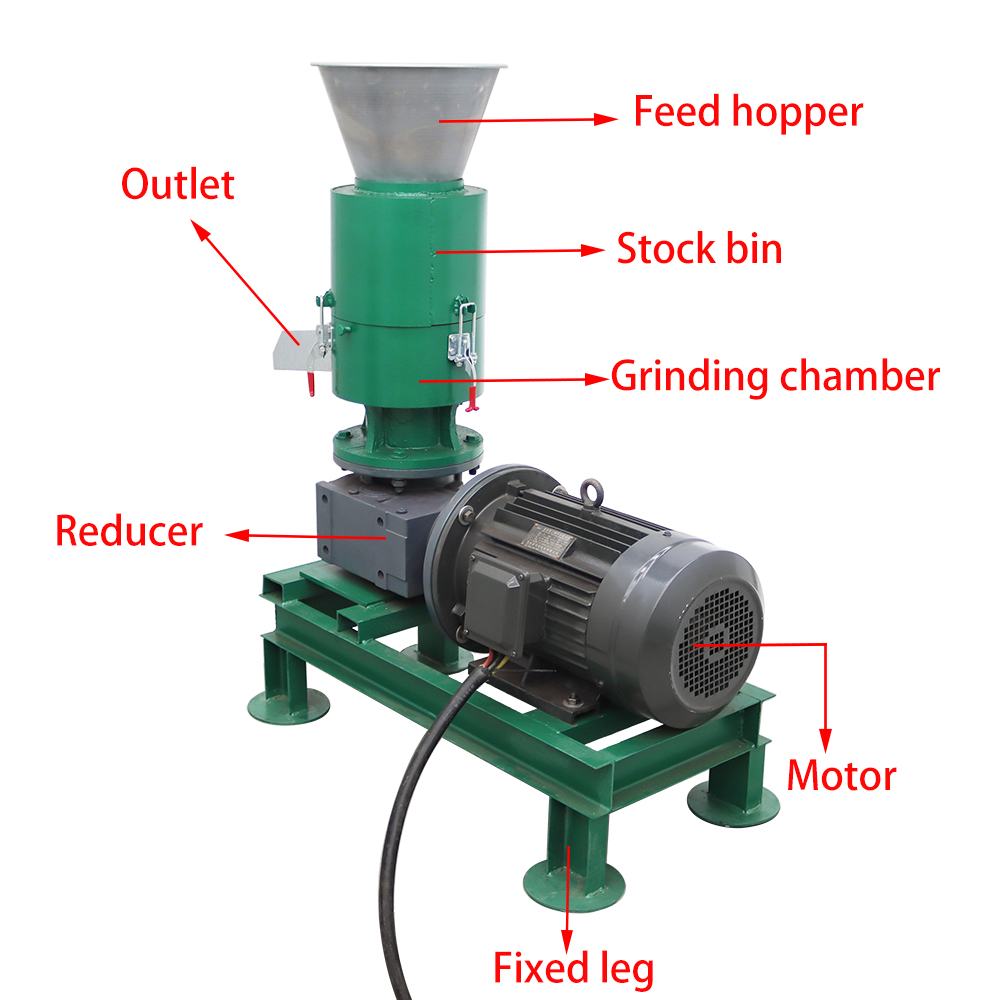

220V Wood pellet

machine 6MM |

|

|

|

|

|

|

|

The small

biomass processing pellet machine is extremely outstanding in terms of

energy conservation and efficiency. It has unique effects and

environmental benefits, and can turn straw and waste into treasure. It

helps us solve the problem of storing or treating agricultural and

forestry waste such as corn straw scales, cotton stalks, wood bran, wood

powder, sawdust, peanut shells, rice husks, etc.

This machine uses waste wood to make fuel, which

can replace gas and natural gas. Moreover, the fuel incineration

displacement is lower, making it more environmentally friendly.

|

|

|

|

Note:

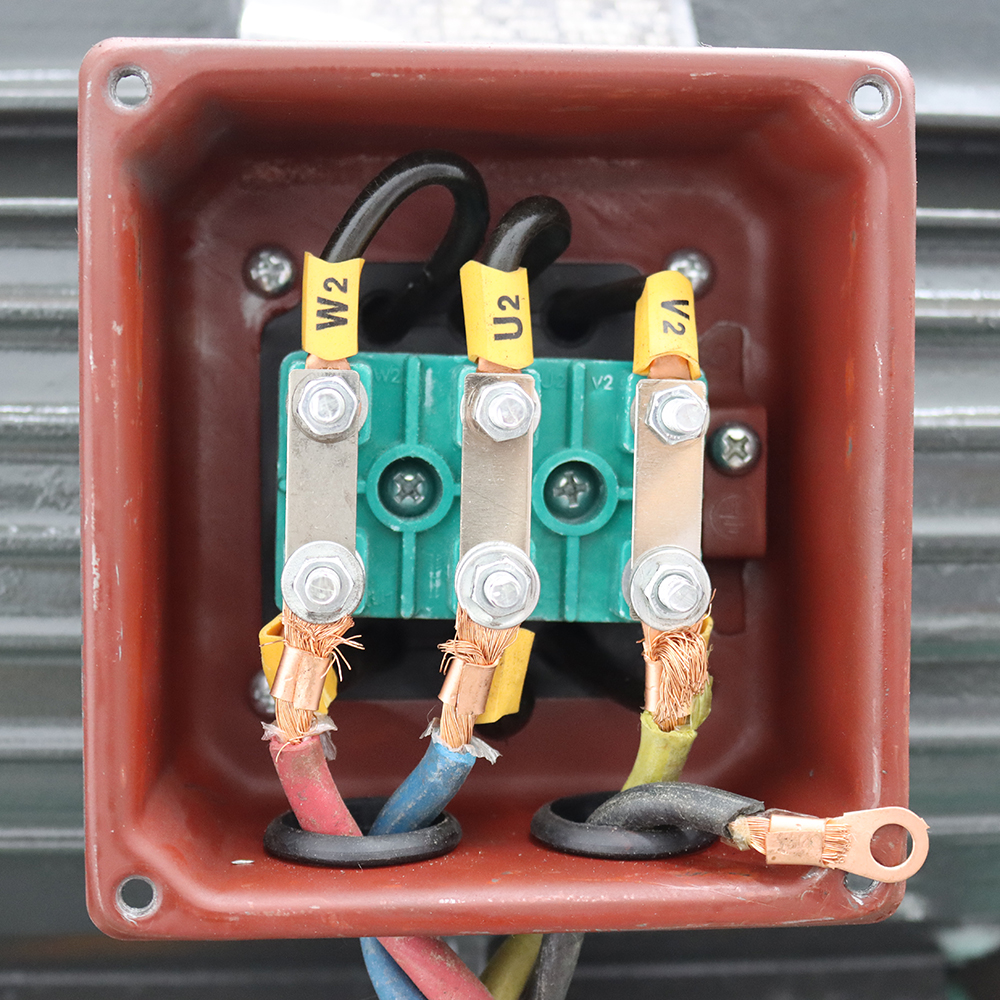

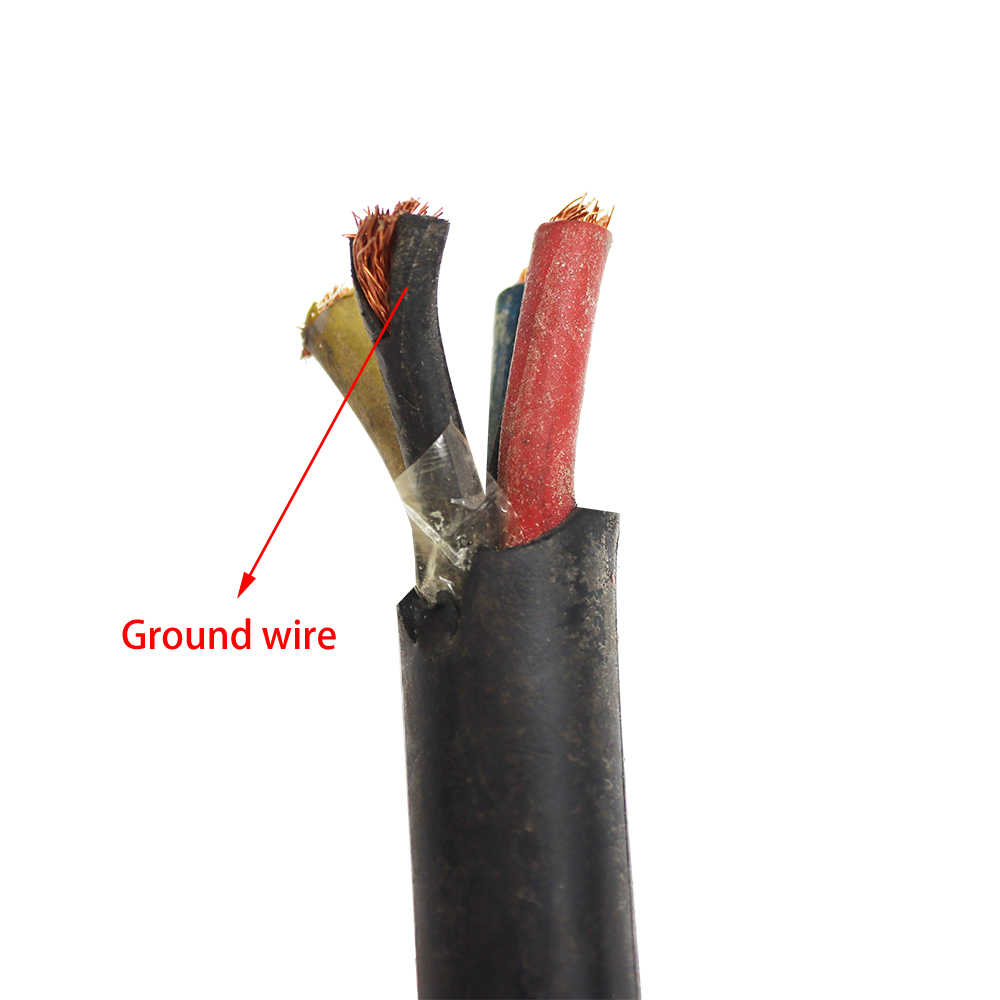

1. This machine is 220V three-phase, please pay attention to wiring

issues when using it.

2. Before starting the machine,open the upper shell of the particle machine to determine if the nut

above the pressure roller is secure. If there is any looseness, use a

wrench to tighten it.

3. After connecting the power supply, turn on the machine to check if

the rotation direction of the pressure roller is correct

(counterclockwise direction).

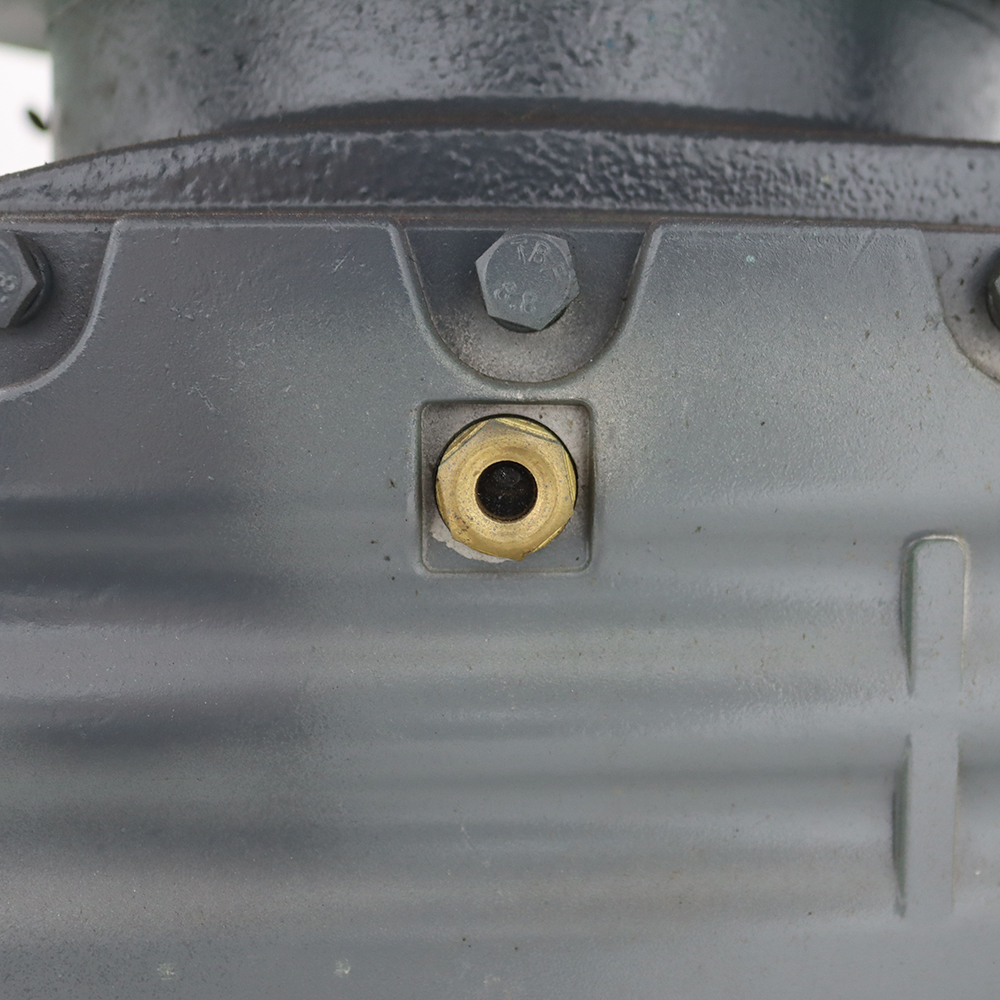

4. Before

starting the machine, please check whether the oil level inside the box

meets the requirements and ensure that it is at the normal oil level

(two-thirds of the oil mirror).

5. Check

the oil temperature after 10 minutes of load operation, and the

temperature rise should not exceed 50 ℃.

6. Please

carry out daily maintenance and do not accumulate dust and oil stains on

the outer frame of the gearbox to avoid affecting heat dissipation.

7.Remove the

rubber ring from the brass vent nut before starting.

8.Replace the

LCKC150#200# gear oil after 500 hours of use for the first oil change.

|

|

Product parameter: |

|

| voltage: |

220V three-phase

electricity |

| Power: |

7500W |

| Production: |

60KG |

| Wood chip particle combustion value: |

3000-4300 kcal/kg. |

| Feed hopper inside diameter: |

11in(28cm) |

| Feed hopper outside diameter: |

12.2in(31cm) |

| Outlet size: |

8.86in*6.1in(22.5*15.5cm) |

|

|

Product analysis: |

|

|

Feature: |

|

This machine is equipped with an

enlarged and widened discharge port to prevent feed splashing and

facilitate the collection of feed by customers. |

|

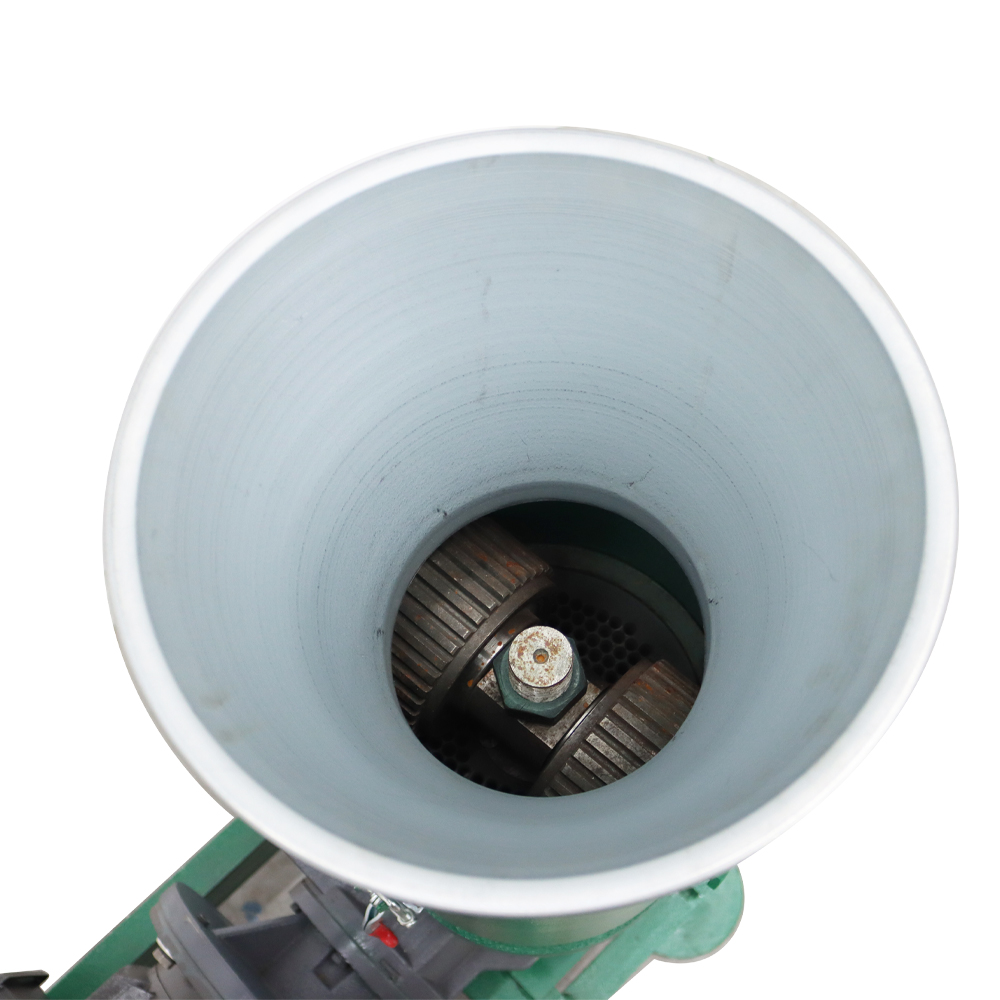

Enlarge the feed inlet

The machine adopts the design of

enlarged feed port, which makes it more convenient for you to feed and

effectively improves work efficiency. |

|

|

Gear oil needs to be added to the

gearbox, and we have already added the oil. (LCKC150 # 200 # gear oil) |

|

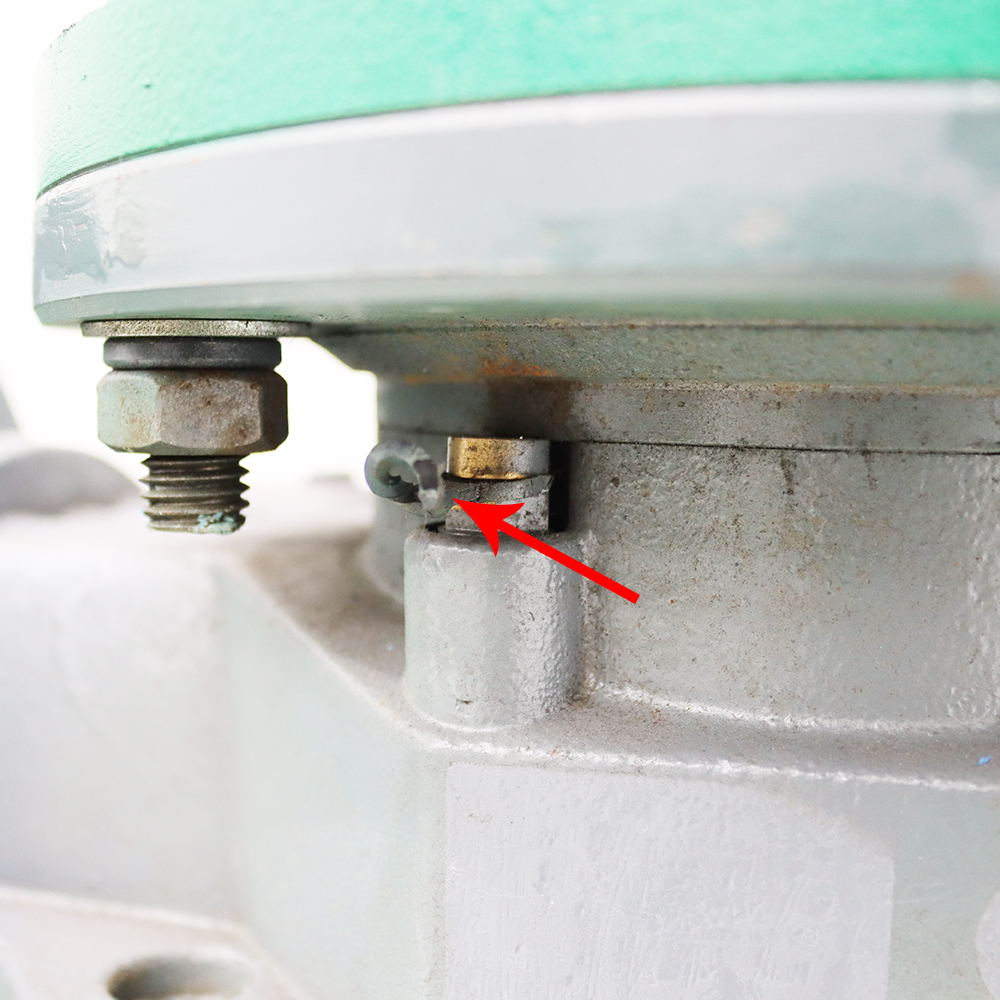

Before using the machine, please remove

this flat 8-shaped rubber ring to avoid oil leakage.

|

|

|

The machine is equipped with air

switch, which is safer to use. |

|

After using the machine for a period of

time, the customer needs to add butter to lubricate the grinding chamber

here (approximately 4-6 months of use) (the butter gun and butter need

to be purchased by the customer themselves, and we do not provide them). |

|

|

Precautions:

|

|

1.When using, it

should be noted that there should be no foreign matter such as stones

and ironblocks in the raw materials. After the pellet machine has been

working continuously for morethan ten shifts, the pressure roller oil

hole, the universal joint oil hole, and the linkage shaft oilhole need

to be filled with high-temperature lubricating grease to make the

pressure roller Goodworking performance and extended bearing life.

2.During granulation, it is strictly forbidden for the pressure roller

to contact with the templateto run idly, and the continuous feeding can

not be interrupted.At the same time, the pressureroller shaft nut is

locked to avoid loosening and damaging the spindle keyway.

3.When granulating, there is no granulation, no discharge, the

template should be removed, andafter opening one by one, some fiber feed

can be added appropriately to restart the granulation.

4.Always

check the tightness of the screws in each part of the machine.

5.When the pellet machine is working, do not reach into the feeding

port with your hands. Ifnecessary, use wooden sticks to help feed the

pellets.

6.Before turning on the machine, it is necessary to add less material

before turning on the

machine. When shutting down, leave a small amount

of feed in the machine to prevent the pressroller of the machine from

contacting the template from idling.

7.If the machine is stuck in operation, stop it immediately, press the

pressure roller until thebolt is flat,and then restart the machine.

|

|

Details: |

|

|

|

|

|

|

The particles

made of wooden raw materials have varying calorific values depending on

the type of wood used, mainly determined by the raw materials. At

present, the main raw materials for wood particles on the market are

poplar, pine, miscellaneous wood, elm, oak, apple wood, jujube wood,

camphor pine, mahogany, and other wooden materials. Hardwood wood is

hard and produces the highest calorific value of products, such as pine,

camphor pine, mahogany, and other soft wood processed products such as

poplar miscellaneous wood and tung wood are generally low in calorific

value!

|

|

Product display: |

|

|

|

|

|

|

Item Number:

1*Wood pellet machine 6MM 220V (239677) |

|

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|

|