|

|

|

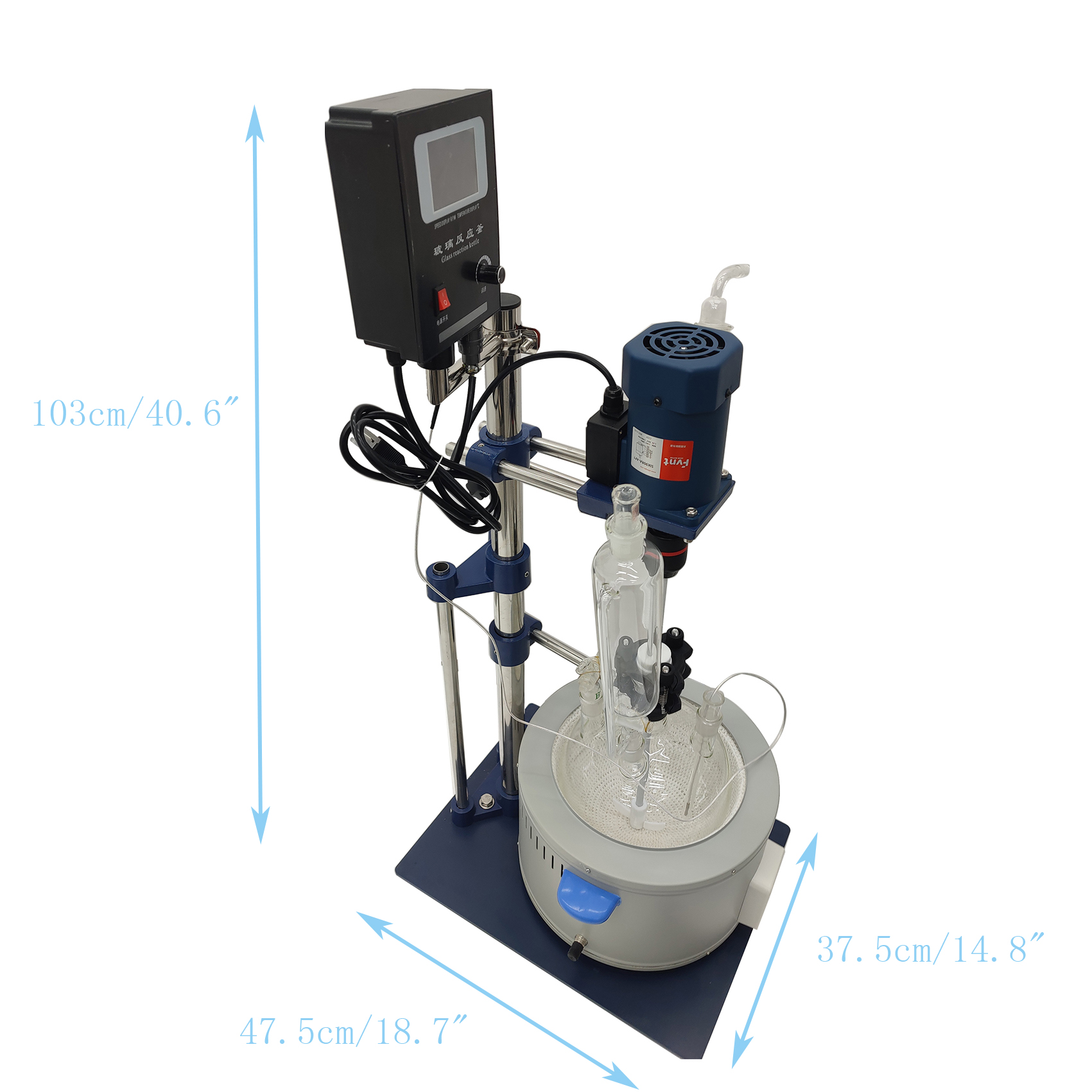

5L

single-layer glass reactor 110V

|

|

|

|

|

|

|

|

Glass reactor

is single-layer glass design,

can do stirring reaction. The reaction solution can be stirred

in the closed glass reactor at the set constant temperature

under the atmospheric or negative pressure condition according

to the use requirements, the backflow and distillation of the

reaction solution can also be conducted, and the glass reactor

is a piece of an ideal pilot test and production equipment

for modern fine chemical industry and new material synthesis.

|

|

Technical parameter

|

|

1. High

quality high borosilicate (GG-17)

material, high quality 304 stainless steel material for the

vertical rod and the fixed frame,

with the advantages of corrosion resistance, rust

resistance,

resistance to various

solvents.

2. Type: single layer

spherical

3. Capacity: 5L

4. Motor power: 90W

5. Speed: electronic

speed regulation 0-600 RPM

6. Power supply: 110V

7. The reactor

can withstand temperature and working pressure: withstand

temperature: -120℃----300℃ (the temperature can be digitally

displayed on the controller) Withstand temperature

difference: +/-40℃, withstand working pressure: normal

pressure and negative pressure (-0.1MPa) The reactor is

equipped with a solid feeding port, the solution at the

bottom is stirred without dead corners, no liquid accumulation.

8.Electric heating

sleeve technical parameters

Power supply: 110V

Capacity: 5000ml

Power: 1100W

Temperature control

accuracy: ±1℃,

Temperature control

mode: intelligent digital display, thyristor control, internal and

external sensor temperature measurement

Heating temperature:

maximum surface temperature 380℃

Boiling: 50ml water

10-25 minutes

Furnace wire:

Cr20Ni80

Extreme edge layer:

no alkali glass fiber, can withstand temperature 450 degrees

Insulation factor:

Dry ≥500 megabytes

Thermal insulation

layer: exclusive use of aluminum silicate cotton vacuum filter type

environmental insulation body

Safety tube: 5×20

15A

|

|

Characteristics

|

|

1.Adopts

a material and

special rubber composite seal ring to seal, can withstand a variety of

different solvents and maintain a high vacuum easy to use.

2.High efficiency

condenser, ensure high recovery rate.

3.Standardized

connection, easy to disassemble.

4.Stepless speed

regulation, no spark motor, safe and reliable.

.

5.The

vertical rod and fixed frame

are made of 304 stainless steel and aluminum alloy material,

with the advantages of corrosion resistance, rust prevention, solvent

resistance.

7.The glass parts

are made of GG-17 high temperature resistant borosilicate glass

material, with good physical and chemical properties.

8. Electric heating

sleeve heating, intelligent constant temperature, easy to clean, no loss.

|

|

Attention |

1, before use, carefully check the

instrument, whether the glass bottle is damaged, whether the

interface is consistent, and pay attention to handling gently.

2, wipe each interface with soft cloth (can be replaced by a

napkin), and then apply a little vacuum grease. (The vacuum

grease must be applied after use to prevent ash sand from

entering.)

3, the interface cannot be screwed too tightly. Be sure to

regularly loosen the flexible part to avoid long-term lock

caused by the connector bite.

4, first turn on the power switch, and then let the machine run

from slow to fast, stop the machine, and then turn off the

switch.

5, the PTFE switch everywhere cannot be excessively tightened so

as not to damage the glass.

6, after each use, the user must wipe all kinds of oil stains,

stains and solvents remaining on the surface of the machine with

soft cloth, and keep the machine clean.

7, after the shutdown, loosen the PTFE switch, otherwise

long-term static in the working state will cause the PTFE piston

deformation.

8, regularly clean the sealing ring, the method is: remove the

sealing ring, check whether there is dirt on the shaft, wipe it

with soft cloth, then apply a little vacuum grease, reinstall it

and keep the shaft and the sealing ring smooth.

9, the electrical part must not be watered, and is strictly

prohibited from moisture.

Must purchase the original authentic parts, the use of other

parts will cause fatal damage to the machine.

When making any repair or inspection of the machine, be sure to

cut off the power and water first.

Note that this equipment is a fragile product, please handle it

carefully when using, the damage of fragile products is not

within the scope of our warranty, if the customer needs, we need

to charge the corresponding cost.

|

|

Installation and

Operation Method |

1. After opening the package, check whether

the main accessories of the machine are complete according to

the packing list.

2. Assemble the frame of the stainless steel pipe and fixed

parts as shown in the attached drawing.

3. Install the electrical box on the top of the right rear

vertical rod, tighten the screw, and plug the cable at the back

end of the electric heating sleeve. Plug in the three-wire

socket. The three-wire socket should be grounded. Set the

temperature according to the heating requirements.

4. Start the motor, slowly adjust the governor knob, the motor

stirring rod is running smoothly. If there is swing, it is

necessary to readjust the concentricity of the motor shaft and

the stirring rod. Adjust it accurately, and the stirring rod can

work without swinging.

5. Turn on the electrical switch. After adjusting it to the

appropriate temperature, the reaction test can be carried out by

heating. After the reaction test is completed, turn off the

power supply in time.

6. The stirring rod is fixed on the clamp of the motor spindle,

and the stirring rod passes through the middle of the cover to

rotate the bearing. Tighten the special connector, and then

adjust the position of the motor. Pay attention to the vertical

concentricity.

7. The slider on the vertical bar is a stainless steel

multi-purpose clamp that is fixed and adjusted in different

directions and heights.

8. The installation of glass instruments must be clean, and the

interface is coated with Vaseline to prevent the phenomenon of

glass holding, and then coated with vacuum grease to prevent air

leakage.

9. After the fixed device is installed, stirring begins. If the

stirring is stable, it indicates that the debugging has been

completed.

|

|

|

|

|

Item Number: 220535

|

|

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.

|

|